SRC wrapped up another year of innovation and evolution with many long-term projects coming to fruition in 2025. With enhanced sensor-based sorting services, the completion of a custom microgrid project and the launch of an Indigenous Action Plan, we have had a lot to celebrate this year.

Join us in revisiting some of the biggest highlights of 2025.

Key Points:

- SRC delivered $657M in economic impact for Saskatchewan in 2024-25 and launched our Indigenous Action Plan

- We worked with SaskPower to complete a solar microgrid for Descharme Lake.

- We recognized our staff for safety leadership and innovation.

- Our Minerals Liberation Sorting Centre introduced a full-scale laser sorting unit for mining.

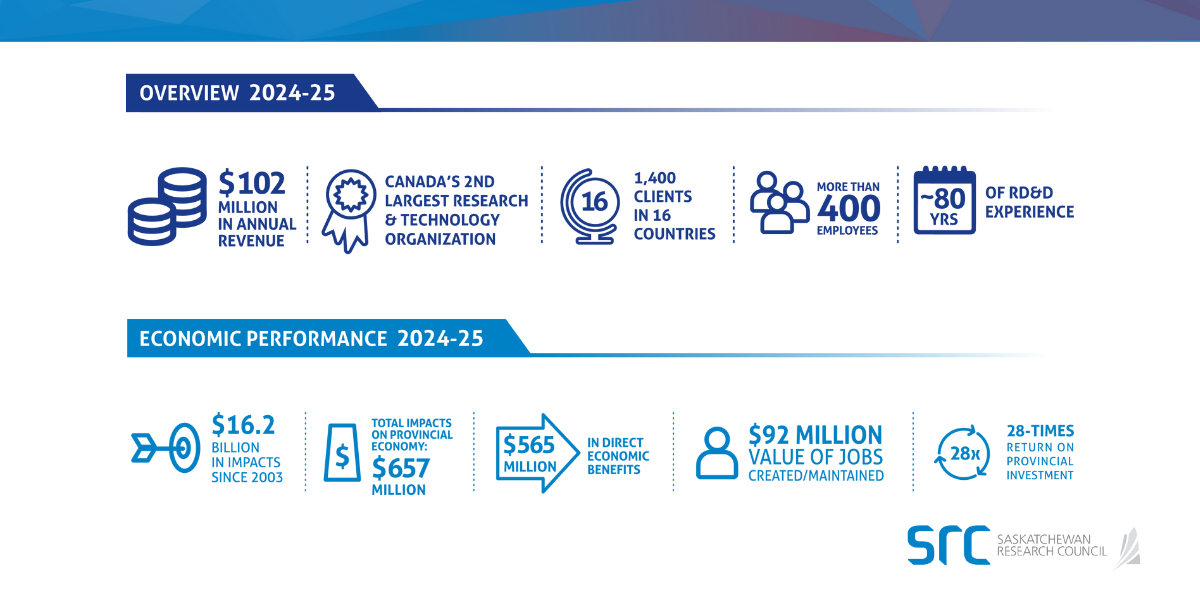

Making Significant Economic Impacts in Saskatchewan

This year, SRC announced $657 million in combined economic and employment impacts in the province. SRC’s annual economic impact assessment began in 2003 and since that time, it has recorded roughly $16.2 billion in combined economic and employment impacts in Saskatchewan.

In the latest assessment, SRC recorded $565 million in economic impact. SRC also assisted in creating or maintaining more than 1,447 jobs in Saskatchewan in 2024-2025, which led to $92 million in additional value.

With a mandate effectiveness of 28, SRC’s work contributed to a 28-times return to the growth of the Saskatchewan economy. SRC President and CEO Mike Crabtree says that these numbers illustrate SRC’s vision.

“SRC is focused on the future – advancing innovation and technology development to deliver real solutions for our clients and industry within Saskatchewan,” said Crabtree.

You can read SRC’s full economic impact assessment news here.

Our Indigenous Action Plan

Building on decades of collaboration and engagement, SRC launched its Indigenous Action Plan in January 2025. Through building trust and strong relationships, the Plan strives to bring Indigenous Peoples, communities and businesses together to achieve shared goals.

This Indigenous Action Plan was built to align with the Truth and Reconciliation Commission of Canada’s (TRC) Call to Action 92, which urges corporate Canada to commit to meaningful consultation for economic development projects, ensure equitable access to jobs and education and provide all staff with intercultural and anti-racism training.

Our plan is built on four pillars: Employment, Leadership, Indigenous Community Relationships and Business Development. Under the Employment pillar, SRC launched two new programs in 2025 – an Indigenous Workforce Program and its Indigenous Summer Student Program, kiskiyihta, which is a Cree word meaning to learn or to know.

Read more about SRC’s Indigenous Action Plan here.

Assisting SaskPower with Descharme Lake Microgrid Project

In 2025, SRC celebrated the completion of a renewable microgrid project for the community of Descharme Lake, Saskatchewan. Working with SaskPower, SRC designed, constructed and commissioned the project which included a custom Hybrid Energy Container.

The container houses batteries, inverters, back-up generators and other technology that is used to provide dependable solar-based energy to the community. Fitted with thick insulation and a multi-stage heating and cooling system capable of withstanding the extreme temperature swings in Saskatchewan’s north, this iteration of SRC’s Hybrid Energy Container is designed to operate efficiently in harsh environments.

The microgrid site includes 474 solar panels and can produce 228 kilowatts of power, replacing a 96-kilometre power line that was nearing the end of its operational life.

Read more about the first independent community power system of its kind in Saskatchewan here.

Safety Remains Top Priority in 2025

As the work at SRC evolves so does its strong safety culture. To celebrate the safety-focused work of employees, SRC holds annual safety awards which recognize its staff’s continued commitment to a safe and healthy workplace.

SRC’s safety awards are comprised of three different categories:

- SRC’s Everyday Role Model award is given annually to individuals that demonstrate leadership in safety while keeping positive and enthusiastic attitudes. We were very pleased to award this honour to Joey and Aaron from our Rare Earth Elements team and to Vince from our Environmental Remediation team.

- SRC’s Safety Prevention by Observation Tool or SPOT allows employees to flag hazards that have potential to cause harm. By reporting these unsafe conditions or actions, SRC can work towards safer working environments. The top SPOT report award goes to individuals who use the program effectively. This year, Rare Earth Elements team members Ashton and Lisa, along with Angela from our Geochemistry team, were recognized for their proactive observations and efforts.

- The Special Projects, Initiative or Innovation award is given to teams that demonstrate exceptional initiatives in improving safety at SRC, helping to reduce risk in the workplace. The Rare Earth Elements R&D team that helped develop a Smelter Furnace Process and Training Program shared this award in 2025.

Read more about SRC’s employee health and safety efforts in our blog here.

SRC Introduces a New Full-Scale Laser Sorting Unit

This summer, SRC unveiled a new full-scale laser sorting unit for its Minerals Liberation Sorting Centre. The Centre offers front-to-back solutions for mining industry clients in all stages of the mining cycle.

With the addition of the laser sorter, SRC now offers full production-scale sensor-based sorting services and laser testing – a world-first for independent testing centres!

Sensor-based sorting offers improved efficiency and reduces waste, improving both environmental impact and operational costs for the mining industry. SRC’s comprehensive three-stage testing method is designed to help clients select appropriate sensor-based sorting technology for their operations. With the introduction of the new laser sorter, SRC is well on its way to becoming a global mineral sorting and separation centre of excellence.

Learn more about the new full-scale laser sorter in this blog post.

SRC’s Rare Earth Processing Facility Sparking Progress in 2025

Next year will be a big year for SRC’s Rare Earth Processing Facility as it’s on track to complete the commissioning process. In the meantime, key parts of SRC’s facility are already capable of commercial production, with full operation on the horizon for 2027.

With the North American rare earth element (REE) market evolving, SRC is exploring new opportunities as facility construction continues, most recently securing a long-term offtake agreement with REalloys Inc. (REA). This company will purchase the vast majority of the facility’s annual production of Neodymium -Praseodymium (NdPr) metal and Dysprosium (Dy) and Terbium (Tb) oxides, providing a stable, long-term anchor customer for the facility. The remaining production output will be available to other domestic and international customers, supporting broader market development and diversification opportunities.

Read more about SRC’s Rare Earth Processing Facility’s progress in our blog post here.

Project CLEANS Wraps Up Another Year of Fieldwork

SRC’s Project CLEANS (Cleanup of Abandoned Northern Sites), a multi-year project to assess and remediate 37 abandoned uranium mine and mill sites in northern Saskatchewan, finished another field season in the fall of 2025.

This year’s annual Leadership Tour welcomed community leaders and government ministry representatives on a site visit to the Lorado Mill Site. The tour held particular significance as SRC prepares the Lorado Mill Site to enter the Institutional Control Program (ICP) process, which will transfer the long-term monitoring of the site to the Government of Saskatchewan.

Remediation of the former Lorado Mill Site was completed in 2016 and since then, SRC has monitored and performed maintenance as needed to ensure that the site is stable and that revegetation is progressing as anticipated. One of the most remarkable findings of the season came from a fish survey conducted in Nero Lake, where an abundant fish population was discovered. This provides compelling evidence of a healthy and recovering ecosystem.

Remediation was completed at two Satellite Sites this year, while hydrological monitoring, environmental sampling, archaeological surveys and other assessments took place at multiple sites. Remediation efforts at the former Gunnar Mine Site are anticipated to wrap in 2026.

As of 2025, 28 sites have completed remediation work with six Satellite Sites remaining. You can learn more about Project CLEANS here.

SRC Improves Clay Measurement with New Technology

Clay minerals can be a significant problem for plant operations. Because they are small and share similar crystal structures, they are difficult to measure, requiring extensive sample preparation or long, subjective processes that lead to less than reliable results.

From potash slimes to kimberlite slurries, a better analytic approach was needed by industry to quickly and accurately measure clay minerals to avoid these challenges. SRC’s Pipe Flow Technology Centre™ responded to this need by developing an Automated Measurement Platform that provides accurate, real-time, clay mineral measurements.

SRC’s Automated Measurement Platform uses technology developed in-house to improve the resolution and accuracy of measurements, coupled with automation that reduces labour and result times.

Read more about SRC’s Automated Measurement Platform for clay minerals in our blog post here.

More to Come

With 2025 coming to a close, SRC looks toward a new year of innovation. One filled with bigger challenges to tackle and many more successes worth celebrating. Follow along as SRC enters 2026 and a new year of global opportunity!