Whether in potash slimes, oil sands or in kimberlite slurries, active clay minerals can cause serious issues in many plant operations. For industries where clay minerals are present, a better analytical approach is needed to more quickly and accurately measure these minerals.

In response to this, experts at SRC’s Pipe Flow Technology Centre™ developed an Automated Measurement Platform (AMP) that provides accurate, real-time, measurement of clay minerals.

So, what are clays and why is it important to know if they are present?

Clay minerals are small, negatively charged particles that are highly reactive in industrial slurries, wastewater and soils. However, their reactivity can vary significantly depending on the chemistry and crystal structure of the mineral.

Industrial processes are affected by the reactivity of the clays present, and how those clays interact with cations in the environment—this is known as the cation exchange capacity (CEC). Depending on what clays are present in an ore, the reactivity or CEC can vary, ranging from small in “inactive” clays, such as kaolinite, to very large in “active or swelling” clays, such as smectite.

Particularly where there is a solid-liquid separation process or pumps, the amount and CEC of the clay minerals present can lead to significant operational problems.

“As soon as a mine has an active clay in it, there's probably going to be a problem, and it’s going to be a big problem,” said SRC Research Scientist Jennifer Bentz, who works at its Pipe Flow Technology Centre™. “It can cause a shutdown or a stop to production to fix the issue or clean it up.”

For example, in the potash industry clay minerals will consume the flotation reagents used to collect potash, increasing processing costs and reducing recovery. They will also clog filters, increase wear on equipment and increase the yield stress of slurries making them harder to pump.

In hard rock mining, such as diamond and uranium operations, clays will stick to crusher plates and liners, gum up the thickener discharge, bog down scrubbing units and require more thickener to settle.

In geotechnical applications, they also cause structural damage to foundations, roads and pipelines due to the shrinking and swelling nature of the clays.

Not only do they cause process problems for minerals processing, but even small amounts of clay can prevent solids from settling and the amount of water that is recovered as part of tailings management and water reuse.

But clays can also be useful

In certain applications active clays are beneficial, like at foundries where they are a key component of molds made with a compound mixture called “green sand” that are used for metal casting. Active clays are also used in cat litter because of their exceptional absorbent and clumping properties, and in water and soil treatments to adsorb contaminants from the environment, such as heavy metals, organics, industrial dyes and radioactive isotopes.

They can also be used as liners for landfills, tailings ponds and heap leach processes due to their very low permeability, which prevents contaminants from escaping into the environment.

Whether a challenge or benefit, it’s important to measure clays

Clays are difficult to measure because they are small and share a similar crystal structure to each other, despite significant differences in CEC.

This means that many of the traditional analytical methods used to measure them (e.g., X-Ray Diffraction (XRD), Fourier Transform Infrared Spectroscopy (FTIR), Short-Wave Infrared Reflectance Spectroscopy (SWIR), and particle size) require intensive sample preparation to get accurate data, sophisticated equipment and robust chemometric models to resolve overlapping patterns.

Historically, the most practical way to detect active clays was a manual technique called the Methylene Blue Index (MBI) because the procedure could be performed in the field without any expensive analytical equipment.

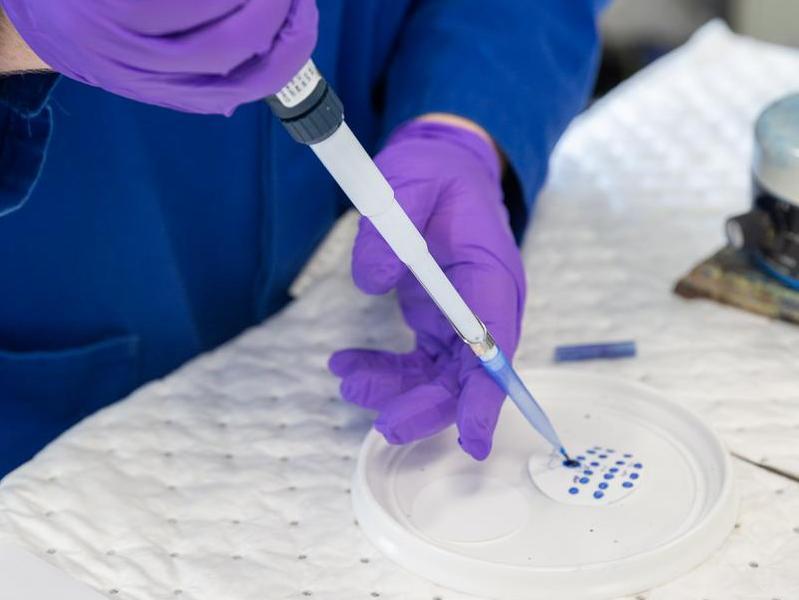

In the MBI method, a technologist takes a sample, then performs a manual titration by carefully adding blue dye to clay mixtures and “dotting” a filter paper after each successive addition. The appearance of a blue halo around a dot signifies the endpoint of the titration, indicating that the clay has absorbed the maximum amount of dye it can hold. The process is straightforward but slow—taking as long as an hour—and relies on subjective assessments from technologists to determine the endpoint.

And this is where SRC’s AMP comes into play. The AMP combines automation and a tailored spectroscopic analytical technique to make on-site measurements of CEC using a cationic dye simpler, faster and more precise.

From concept to real-world application: SRC’s solution to the challenge

In 2019, SRC received funding from Natural Resources Canada's Clean Growth Program to develop an at-line automated clay analyzer for oil sands applications. With support from its project partners, SRC developed a separate prototype during the project based on its own technology design. SRC’s prototype was later successfully validated during a field trial.

Field testing was key, as according to Bentz, “The problem of going from benchtop to a large-scale industrial setting is that everything can get more complicated and doesn't always work. But that’s the power of SRC—the team is really good at the kind of innovation and automation needed for scaling-up technologies.”

The clay analyzer performed so well at precisely analyzing the CEC value (in this way deducing the clay content) in tailings slurries that SRC is continuing to develop the technology for other industrial applications.

Let’s take a closer look at how the AMP evolved.

Stage one: improving reliability

SRC replaced the visual endpoint determination of the MBI method for clay measurement widely used in industry with a spectrophotometer. This increased the resolution and accuracy of the measurement, now possible due to technological advancements that have made spectrophotometers smaller and more mobile and cost effective.

“We can detect changes down to micromoles that the human eye cannot,” Bentz said. “We've taken that subjective variability right out of the equation, and it's much more reliable.”

However, the spectrophotometer requires adjustments based on different applications.

These adjustments include optimizing the amount and concentration of cationic dye needed, which requires additional time for saturation and to produce a clean, filtered sample, depending on what is present in the slurry (e.g., solids, bitumen).

Moreover, the spectrophotometer requires daily initialization that requires a degree of specialist knowledge.

Despite these roadblocks, the spectroscopic method has started to become more popular in laboratories due to the speed and reliability of the measurement. SRC terms this the manual spectrophotometric method and supports industry in implementing it as a first stage to more reliable testing.

Stage two: adding automation

However, the real advancement of this technology is that SRC went further and automated all the steps in the process into an Automated Measurement Platform (AMP) that can also connect to process lines for on-line capabilities.

The AMP performs every step of the spectroscopic CEC measurement, including accurate chemical dosing of the buffer solutions and cationic dye, dispersion and mixing of the samples, automatic subsampling and filtration down to 0.45 microns and the daily initializations required by the spectrometer. It also contains built-in calculations to give the operator or lab technician the final CEC of the sample—all with custom software programmed at SRC.

To make this work at industrial-scale and for different applications, the team needed to optimize the exact concentration and dosing of the cationic dye for maximum efficiency and accurate detection of the clays, depending on inputs.

“The good news is we really perfected this for a whole range of different samples, and the team has this basically down to a science of how to get the right recipes,” Bentz said.

With the AMP, industries can now receive a reliable reactivity measurement (i.e., estimated active clay measurement) of the solids in fifteen minutes, a drastic reduction in result times. This helps laboratories to increase the number of samples that are processed and the reliability of the results.

For applications within the plant (termed “at-line”), the AMP only requires the operator to input the sample and apply changes to operational settings on the line in response to detector outputs. Sample preparation, detector calibration and cleaning are all automated.

Now to put it on-line

An on-line solution goes even further by helping processing plants prevent recovery losses or unplanned shutdowns by quickly and reliably detecting the presence of active clays.

“Right now, almost every industrial offering for clay analysis is off-line. By bringing the analysis to the field and connecting it to an automated sampling system such as SRC’s Automated Measurement Platform, this drives down the analytical time to roughly 15 minutes, providing near-real-time data,” said Ruijun Sun, a Senior Research Engineer at SRC’s Pipe Flow Technology Centre™.

“The goal of the platform is to put it right on the production line and have it provide data to the process control that would automatically adjust the flocculant dosages in a tailings line, for example,” Bentz said.

Applications for other industries

Beyond mining, the Automated Measurement Platform could be beneficial to the foundry industry, which use active clays like bentonite in their green sand molds. They regularly measure clay levels to adequately refresh the spent green sand.

Automating the CEC (or clay) measurements with the AMP could make foundry processes more effective and reduce waste, helping lower costs by maximizing the reusability of the sands throughout the production cycle.

SRC is also looking at applications for the AMP beyond clay measurement.

With an established reputation in potash in Saskatchewan and beyond, the potash industry is one key area SRC is looking to support with the AMP.

For potash processing, insolubles—in this case, clay minerals that aren’t necessarily active—can pose challenges. Insolubles in the brine, especially if clays are present, affect separation and flotation, absorb chemicals and decrease recovery. They may clog filters, wear down equipment and require more reagents.

In tailings management, getting near real-time data on the clay content of tailings can aid in determining optimum flocculant dosages and prevent settling issues in the tailings.

The AMP also has potential in several applications beyond active clay and insoluble particle detection. It can be configured to perform other analytical measurements, including pH, conductivity or water hardness.

“We can really tailor it to perform a wide range of automated analytical measurements,” Bentz said. “It just takes beta testing, and making sure all the sequencing within the platform happens in the right order and that it’s optimized for the client.”

For each new analytical method, SRC tests and validates the platform for the specifics that are unique to each industry. With the core instrumentation and methodology established, many of these other applications are sure to follow.

SRC has patents pending for the Automated Measurement Platform in Canada, the US and Brazil.