As the potash industry has developed in Saskatchewan and around the world, SRC has provided technological support along the way. Learn how we've helped to address many of the potash industry’s challenges and growth along the way.

Meet Mike McCubbing, manager of SRC's Diamond Laboratory - one of the largest commercial diamond processing labs in the world. Learn more about Mike's career at SRC and how his team has helped grow SRC's diamond capabilities to meet evolving industry needs.

As electric vehicle technologies advance and the energy transition continues, the demand for critical metals keeps rising. Learn about SRC's direct recycling process of LIB metals that will help industry meet the growing demand for critical metals and divert batteries from landfills.

A chemical engineer by profession, learn how Dr. Muhammad Imran's career transitioned from oil and gas to mining, and how he and his team are working to build a secure supply chain for rare earths in Canada.

Dr. Jack Zhang and SRC's Mineral Processing and rare earth experts are making waves in industry with their innovative approach to developing processes for ore beneficiation, separation and hydrometallurgy. Learn more about how Zhang built a mineral processing team at SRC from the ground up and what's next for rare earths. Read on.

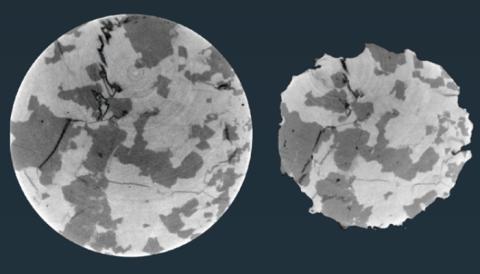

Potash solution mining is used for extracting ore from deep underground, but unlike conventional mining, operators don't have direct access to the potash bed to analyze the geology. This is where SRC's industrial computed tomography (CT) scanner comes in. Learn how CT scanning can help mines better understand their deposits.

SRC hosted a panel event with four industry experts for a discussion about the progression of historic mining practices—the legacy issues we face today and what we may face tomorrow, and what sustainability really means. Read part two of the discussion.

Clays and active clays are found naturally in mineral deposits and present challenges for mining and oil sands industry processes and tailings management. Learn more about the work being done by SRC and its research partners to further the development of two active clay analyzers to address the issues that active clays present.

The way we extract and process resources is constantly changing. The practices and technologies (and legacies) in place today reflect past industry standards. What are the potential legacies of the future? How can we avoid them? Four industry experts weigh in.

X-ray transmission (XRT) sorters are a popular choice for mineral processing plants due to their sorting ability, robustness and applicability across a variety of ores, but how can a mining company know if XRT is right for them? Learn how SRC experts combine technologies to help find the answer.