Canada’s mining industry is vital for the country’s economy—even more so as Canada recovers from the COVID-19 pandemic. SRC is always looking for ways to improve processes, increase productivity and reduce environmental impacts in mining and mineral exploration.

In 2019, SRC was awarded $1.98 million from Natural Resources Canada’s Clean Growth Program to work towards the development of an active clay analyzer for the Canadian mining industry. This technology aims to have the potential to provide near real-time measurements of active clay content in ores and tailings for the oil sands and mining industries. The project partners include Suncor Energy Inc. and Northern Alberta Institute of Technology (NAIT). Overall, including in-kind and other financial contributions, the project is worth $2.78 million.

Clay in Mining

Clays and active clays are found naturally in mineral deposits and present challenges for mining industry processes and tailings management. The work being done by SRC and its research partners is to further the development of two active clay analyzers to address the issues that active clays present in mining processes.

Oil Sands

Oil sands companies are continually looking for ways to reduce their environmental impact, and better managing water and related active clays are part of that work. Active clays cause slow settling and stable suspension in oil sands tailings ponds. “While active clays only make up 10 per cent of clay minerals in oil sands, they present challenges to tailings management,” says Ruijun Sun, senior research engineer at SRC’s Pipe Flow Technology Centre™.

Kimberlite

Active clays are not only a challenge in the oil sands. In South Africa, kimberlite tailings ponds have similar issues. In this setting, without treatment only about 17 per cent of water can be recycled, with much larger amounts of water being tied up in stable suspensions. Samples analyzed from a kimberlite tailings pond showed that active clays were the issue.

Active Clays

Active clays behave differently than other minerals, presenting their own unique challenges in tailings management. “Active clays can impact many mineral processes from extraction to thickening to water recovery," says Sun. "Unfortunately, clays cannot be selectively and effectively removed. We have to deal with them."

“It is our hope that the online and at-line instruments developed in this project will help mining operators address active clay challenges," says Sun.

Clays are phyllosilicates minerals, which are defined as hydrous aluminum silicates with a layer or sheet structure. They are exceedingly small particles—less than two microns. Active clays such as Smectite can produce crystalline and osmotic swellings when they encounter water. The swelling can lead to clay particle rupture, making particles even smaller and creating stable suspensions.

As well, active clays are susceptible to cation exchanges; active clays can also transform into inter-stratified and mixed layers. These mechanisms create more activity, more swelling and additional challenges.

Active Clay Detection

“It is very important to detect active clays in mine operation and mineral processing so we can achieve better process control and avoid producing large amounts of tailings affected by active clays that we must clean up many years later,” says Sun.

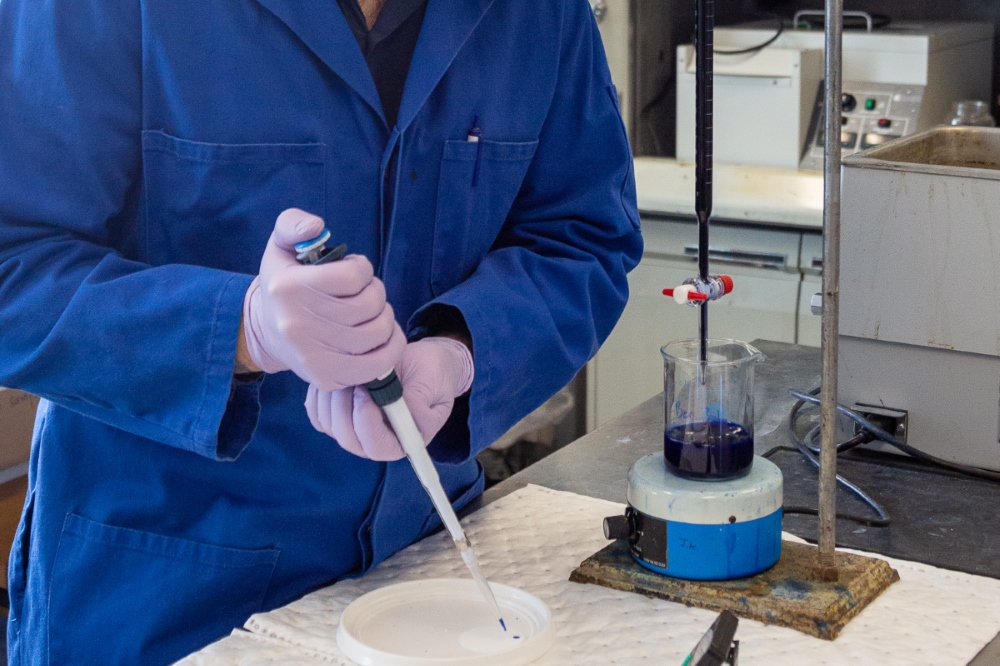

Currently, active clays in mineral samples are determined by the ASTM C837-09 Methylene Blue Index (MBI) method. It is a titration method performed in a chemistry lab which is lengthy, manual and subjective, and there is no automated or online clay analyzer instrument available.

Under the Clean Growth Project, the team is working to develop two types of active clay analyzers. Both systems have different strengths and will have the potential to help industry improve the rapidity and accuracy of MBI measurements.

NAIT is leading the development of an at-line instrument that uses optical detection to determine the end-point. This system is more accurate than the manual lab method as sample preparation has been standardized and the detection method no longer relies on the subjectivity of the operator’s vision and interpretation of the endpoint. The at-line system is designed for use in a field lab.

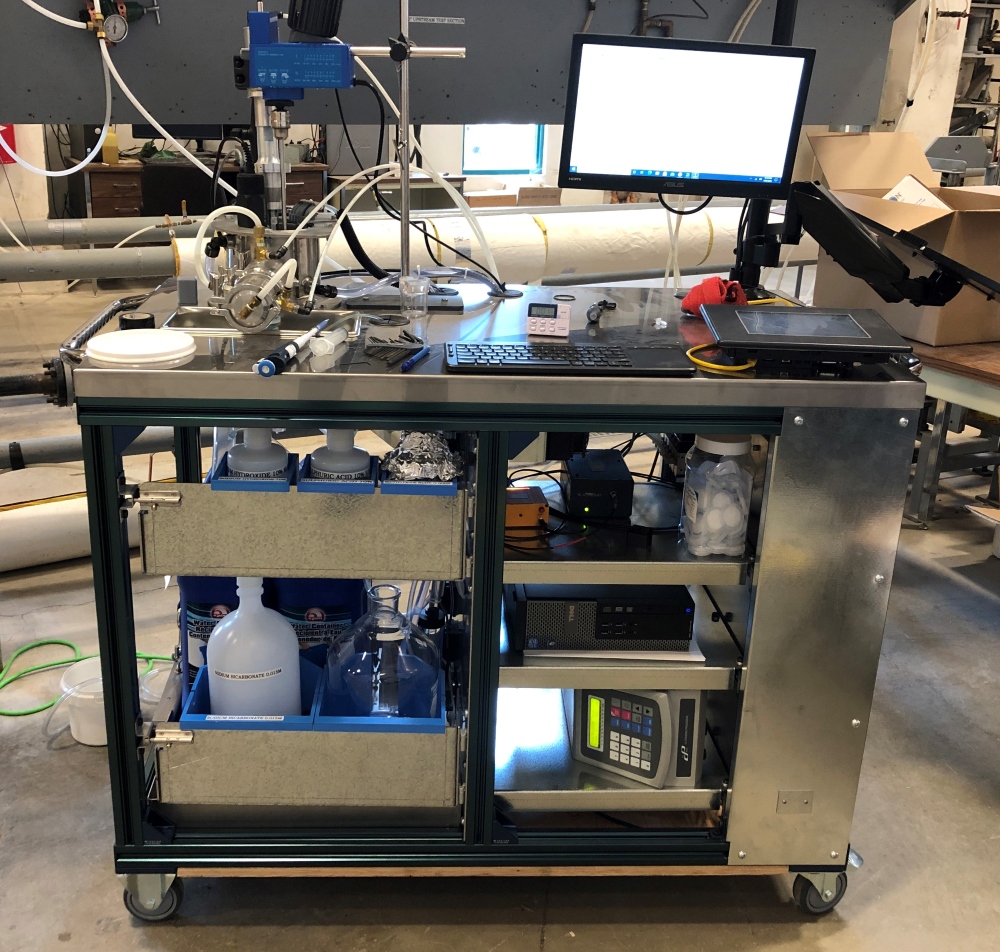

SRC is leading the development of an online instrument that would be installed on a pipeline and automatically withdraw and analyze samples. SRC's system takes a different approach than the ASTM C837-09: it measures spectra absorbance of filtrate that is automatically extracted from mineral samples withdrawn from the process. It is then correlated to the spectra absorbance to MB volume and uses the correlation to determine active clay and clay activity in the sample. The analyzer is automated, online, and will provide results in near-real time for the operators to achieve better process control.

Clay Analyzer

SRC’s active clay analyzer is being developed and tested with hundreds of mineral samples, including three types of industrial samples: oil sands mature fine tailings, kimberlite slurries and potash slimes. The design criteria includes automated online connection, and self-cleaning, continuous operation, where the results will be available in 30 to 40 minutes, allowing for near-real time process control.

The system can tolerate trace amounts of hydrocarbons to reduce sample preparation procedures and requires no human handling of the samples.

“It is more objective and accurate than the current ASTM/CANMET methods, and the system is being designed to be robust and easy to maintain,” says Sun.

Research and development work is ongoing, with system integration and validation occurring in the spring of 2021. “We will complete the lab and field validation tests during the summer” says Sun. “The objective for this work is to develop a better system to detect active clays and clay activity in near real-time. That information can then be used to monitor and control process parameters such as flow conditions, process aid dosages and flow rates.

If we can detect and quantify active clays as early as possible, we can recover more water, reduce tailings volumes and footprint and reduce the cost of future reclamation. In addition, based on SRC’s platform, we are developing an online pH and water hardness analyzer for applications in the oil sands and mining industries.”

This post was written by Brook Thalgott, a former SRC employee.