Workplace safety has evolved a lot in the last few decades. During this evolution it has become evident that a successful safety program requires a team effort, at all levels.

At SRC, safety is seen as everyone’s responsibility, and we have built our culture on that principle. From lab operations to project management to services and products for clients, safety is fundamental to everything that everyone at SRC does.

With a commitment to achieving world-class excellence in safety performance, SRC established a safety program to ensure everyone is involved and engaged. It starts when an employee joins SRC—no matter which division they work in or what their job title is. They are provided with safety training from day one. The culture at SRC reflects the shared responsibility and shared goal that employees go home safe each and every day.

Now that we have established how important safety is at SRC, meet the person responsible for engaging and leading the entire organization with a safety-first mindset.

Meet Sunil Sohani, Director of Health, Safety, Environment and Quality Systems

With a background in engineering and a master’s degree in health and safety, as well as many years’ experience leading teams in occupational health and safety, Sunil Sohani’s expertise helps SRC to continuously improve and move forward on its commitment to safety.

“The main objective of our corporate Safety Services team is simply to establish a safety-first culture across all of SRC,” says Sohani. It sounds simple, but the work this team does is not just a paperwork exercise of creating policies and procedures, it goes much further. “A culture must be created that emphasizes SRC’s policy of safety as the overriding priority, which means that a job cannot be done unless it is safe to do so,” Sohani explains.

SRC’s safety program is based on a management system applied across all the business units of SRC. “Some business units are exposed to unique risks, and our safety program allows flexibility for these groups to have specific safe-work practices or standard operating procedures, with oversight from Safety Services,” says Sohani.

“Examples of safety processes that are followed across SRC are risk assessments, job safety analysis, incidents reporting and investigation, health and safety committees and emergency drills and exercises.”

Sohani and his team maintain constant communication with all managers and supervisors to ensure everyone is on the same page and keeps safety top of mind.

With a diverse group of business units—each having their own set of hazards and risks—and many unique projects that also bring in additional hazards and risks (e.g., remediating abandoned mine sites in northern Saskatchewan, industrial stack sampling, repetitive tasks in the lab), leading this initiative keeps Sunil and his team on their toes.

Top-of-Mind Safety for Success

Safety starts with SRC’s management team, who reiterate during their day-to-day interactions with employees just how important safety is in every step of every job. “It needs to be practised and heard every day,” advises Sohani. “It only takes one misstep for an injury to occur.”

Discussing safety at the start of every meeting, regular safety training, specific safety meetings and communicating lessons learned from incidents via safety alerts all help to keep safety top of mind for employees while they work.

Sohani believes that to avoid communication overload there is a fine line between constant messaging and just enough. “You cannot bombard people with safety messaging or else they become immune to this communication,” says Sohani.

While communication in safety can be a challenge faced by leaders, they also face another challenge—complacency.

When a safety program is successful and incident levels are decreasing, complacency becomes an issue. “People start to think that nothing is happening, so we have nothing to worry about,” says Sohani. “This is the time that really motivates me, as a leader, to adopt proactive and preventive strategies.”

Helping people live a safer life is the main motivator for Sohani in his role. “Moving from engineering to safety has been very rewarding because typically people go to work to earn a living and I earn my living by helping these people stay safe so they can continue earning money,” reflects Sohani. “Helping people to go home safe and bring safety home with them is the best part of my job.”

How to keep employees engaged in safety

To ensure that employees from different business units work together as a team, they need to be kept engaged and involved in safety efforts. “It is important that safety tools, forms and processes are user-friendly, initiatives or events are fun-filled and enjoyable for employees to be engaged,” Sohani says.

At SRC, this is done through various initiatives coordinated with the help of its Occupational Health and Safety Committees. Some examples of such initiatives include a personal protection equipment (PPE) fashion show, hazard identification quiz contests, a Seat Belt Convincer to demonstrate the importance of buckling up and a presentation by an expert from the Public Safety Agency of Saskatchewan on emergency alerts and response systems.

“SRC has a safety award program in place for added motivation to recognize employees who contribute to improving safety standards. There are three categories of awards given each year—everyday role model, special project, initiative or innovation, and top hazards reported,” Sohani says.

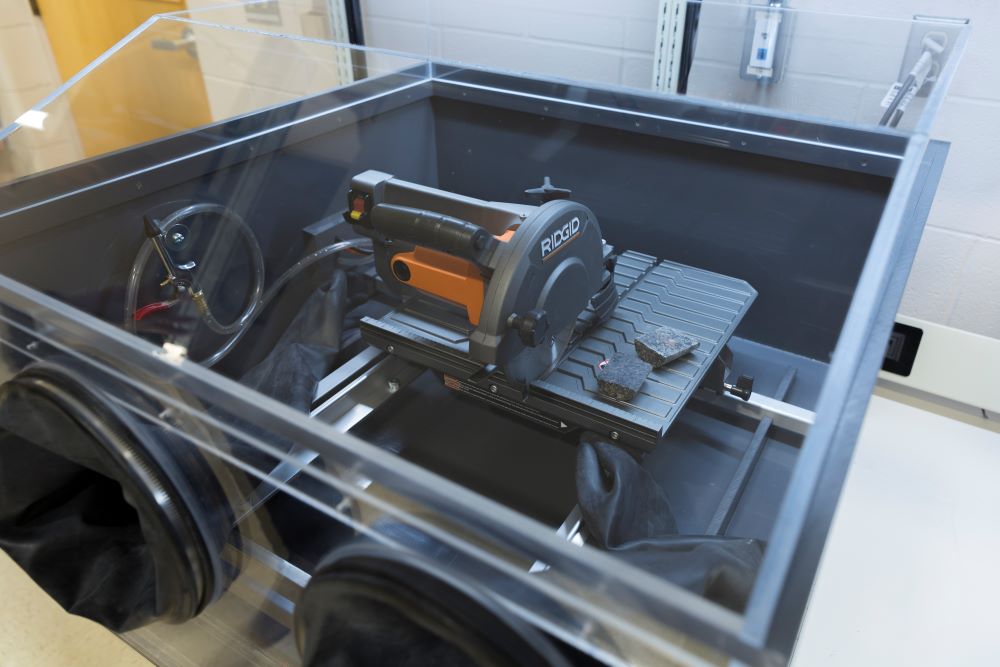

Over the years, employees have come up with innovative ideas to improve safety in the workplace, such as designing and building a glove box to safely cut radioactive core, developing a safe work system to work with hydrogen sulfide, and designing and implementing a diamond recovery circuit involving X-rays.

The Future of Workplace Safety

As we look to the future of health and safety in the workplace, new technologies will continue to have major impacts on the systems we use to monitor and manage safety. Artificial intelligence (AI) is growing rapidly and other advancements, such as digital processes, wearable technology and advanced data analytics software have emerged in the last several years.

At SRC, reporting unsafe acts or conditions and near misses and incidents has already been converted to a paperless, online digital system and is available to employees on smartphones, tablets or computers. The next short-term plan is to convert various safety forms (e.g., inspections, risk assessments and job safety analysis) to digital forms and make them available to employees on mobile devices or computers.

Further use of technology and AI tools will be explored and considered in the future as part of SRC’s continuous improvement to achieve its end goal of getting everyone home safe.