SRC is laying the foundation for Canada’s rare earth element (REE) supply chain with the development of a first-of-its-kind Rare Earth Processing Facility in North America.

REEs are a group of minerals that are used in green technologies like electric vehicles and wind turbines and play key roles in our day-to-day lives — allowing us to stay connected with cellphones and electronics.

Saskatchewan’s long history of mining critical resources makes the province a unique leader in REE processing.

“Canada has some of the largest known reserves and resources, measured and indicated, of rare earths in the world,” says Dr. Muhammad Imran, Vice-President of SRC’s Rare Earth Element Division. “So, it makes sense to kickstart the industry where the resource availability is.”

SRC’s vertically integrated, commercial, demonstration Rare Earth Processing Facility is positioned to stimulate Canada’s resource sector.

Building the REE supply chain

REEs are a group of 17 minerals that aren’t exactly rare but are difficult to obtain in high enough concentrations.

REEs can be recovered from monazite — a material rich in phosphate and other minerals that can be found in either sand or hard rock. To separate the REEs, the monazite must go through several stages of processing and purification.

SRC’s Rare Earth Processing Facility consists of three crucial units: the Monazite Processing Unit, the Separation Unit and the Metal Smelting Unit.

“Rare earths are not really different from other mining sectors when you look at the raw material,” says Dr. Imran. “REEs are separated from impurities in the Monazite Processing Unit. Once that process is complete, the rare earths need to be separated from each other and that’s where the Solvent Extraction Unit comes in.”

Solvent extraction is a necessary step that makes REEs more valuable. Once this stage is complete, the separated rare earths can be converted into metal in the Metal Smelting Unit.

At SRC’s Facility, solvent extraction will separate the rare earths into three mixtures: medium/heavy REEs, lanthanum/cerium carbonate and a neodymium/praseodymium mixture, which then undergo further processing in the Metal Smelting Unit.

Designing and Manufacturing solvent extraction cells in-house

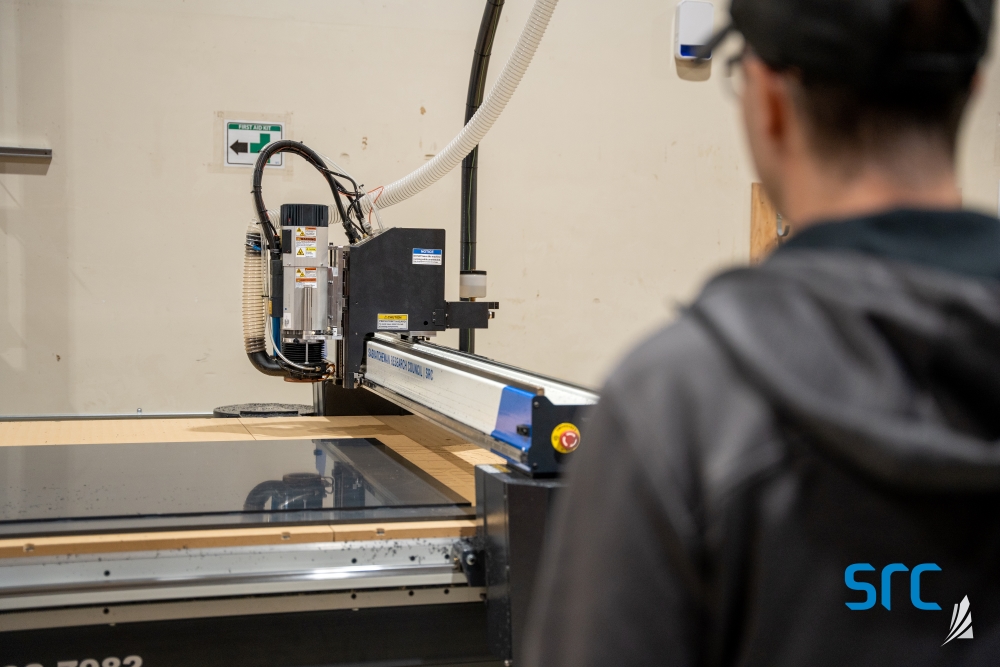

To get the Rare Earth Processing Facility up-and-running, SRC took on the challenge of designing and fabricating solvent extraction cells in-house.

“When we started this project back in 2020, our plan was to procure these cells internationally, but a new export law in that jurisdiction put a ban on any technology related to REE,” says Mike Crabtree, SRC President and CEO. “We tried to get the cells from other countries but ultimately, we thought we should do what we do best as a research and technological organization, and decided to design and build the solvent extraction cells ourselves.”

SRC’s patent-pending solvent extraction cells have been designed with automation algorithms that improve their efficiency and recovery capabilities. They are being manufactured in-house at an SRC-operated fabrication facility.

"Saskatchewan has a rich history in equipment development, innovation and manufacturing for the agriculture and mining industries, so developing this technology for REEs was a natural next step," says Erin Herman, Associate Vice-President of Engineering and Manufacturing in SRC's REE Division. "SRC is fortunate to have in-house experts in REE separation, so developing this technology was something that the Council was ideally suited for."

These cells are fabricated from locally-sourced PVC material that is welded into shape. To address the challenges of PVC welding, SRC has developed semi-automated welding equipment to improve performance and reduce physical demands.

Once fabricated, the cells are assembled into a modular unit called a “battery.” Each battery can hold up to six individual cells.

SRC is building the REE supply chain one cell at a time — by the end of 2023, 140 solvent extraction cells will be fabricated and ready for use in the Separation Unit of SRC’s Rare Earth Processing Facility.

The skills and expertise for the job

With over 75 years of innovation experience, SRC has a proven safety record and the expertise needed to handle the intricacies of REE processing. As Canada’s second largest research and technological organization, SRC has unparalleled experience in mining and mineral recovery.

“REE processing is quite complex and includes the use of chemicals, large quantities of water and skilled techniques. The process must also follow strict environmental regulations,” says Imran. "You need to have the expertise and the capabilities and that’s where SRC really shines.”

From the safe operation and decommissioning of a SLOWPOKE-2 research reactor to the management of Project CLEANS — a multi-year, multimillion-dollar project to assess and reclaim abandoned uranium mines — SRC regularly works closely with industry, regulators and communities.

“The work we are doing has a substantial impact on the overall economy of Saskatchewan,” says Dr. Imran. “Those economic benefits are in the form of jobs, improved productivity, process optimization and delivery of new concepts to commercial applications.”

The construction and daily operations of the fabrication facility and the Rare Earth Processing Facility requires substantial collaboration between SRC and industry and provides both short and long-term employment for local companies and individuals across Saskatchewan.