Inside SRC

The Saskatchewan Conservation House was a demonstration house built to test energy-efficient methods. Four more energy-efficient demonstration homes based on SRC’s research and expertise were later constructed. Learn about the innovative features of these homes that influenced energy-efficient housing across the world.

As a result of the energy crisis in the 1970s, Saskatchewan residents were looking for ways to reduce energy costs for their homes. Learn about the development of an energy conservation demonstration home, the Saskatchewan Conservation House, which applied cost-effective methods for reducing energy use for homeowners.

Making predictions about the future is difficult but, if the past is any indicator, some future technological innovations will arise out of things that have already been imagined by science-fiction and fantasy-fiction writers.

We’re fortunate that many women in STEM careers have chosen to work here – scientists, engineers, researchers, technologists. Learn how five women at SRC came to be in a STEM career and what and who inspired them - and continues to inspire them - to stick with it.

Since the early 20th century, Canada's research and technology organizations have been interested in learning how to measure the economic impacts of their work. Find out how SRC's R&D impact assessment tool works.

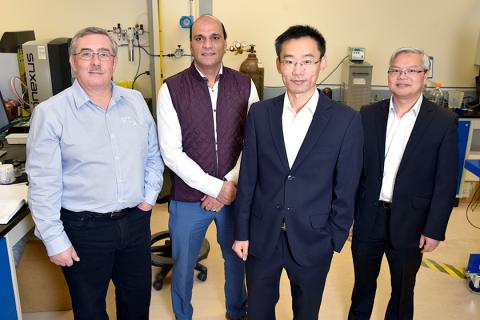

Research programs that foster collaboration between industry and academia are an effective way to support industrial and social innovation. Learn about a recent mentorship that led to a ground-breaking discovery for the oil and gas industry.

In 2001, SRC set out to become more entrepreneurial, grow in breadth and depth, and include more work for communities (particularly northern and Aboriginal communities) and for government.

We’re encouraging people (kids and adults!) to turn their kitchens and backyards into science labs this summer and unleash their inner scientists using a few simple ingredients - no laser ablation mass spectrometer* required!

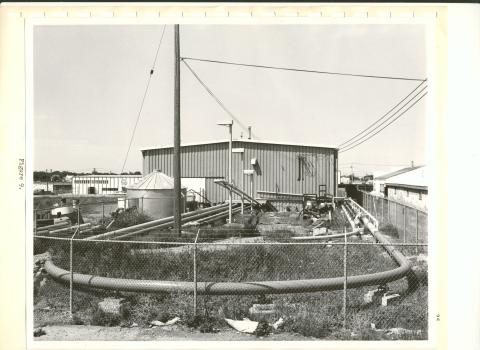

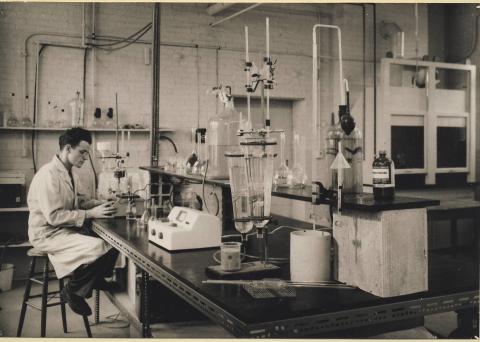

SRC's Maturing Years were marked by growth in staff, facilities and equipment and a focus on applied R&D projects for industry and community needs. This led to the next phase of SRC's evolution, the Commercial Years, which were dominated by contracts with a mostly market-driven outlook, increasing SRC's revenue and importance as an innovation enabler for industry.

Nineteen forty-seven was SRC’s first full operating year. The initial strategic direction for the company was to undertake applied research targeted at developing “the resources and economy of Saskatchewan.”