This is an archived post. SRC no longer offers cannabis testing.

Although cannabis edibles became legal in October 17, 2019, many consumers were surprised that edibles weren’t available that day. Just like when recreational use of cannabis became legal, many factors hindered product availability, including necessary regulation to ensure product safety.

It takes Health Canada at least 60 days to review and approve an edible product for sale. Since it was not possible to begin this review process before edible products were legal, the earliest that edibles could have been available was December 2019.

In practice, many edible products will take much longer to reach store shelves. There are many complexities related to product development, food production and cannabis handling that impact the timeline between product development and sale to the consumer. There is a lot of work for producers to develop the necessary processes, so they are compliant with regulations.

Validation Methods for Edibles

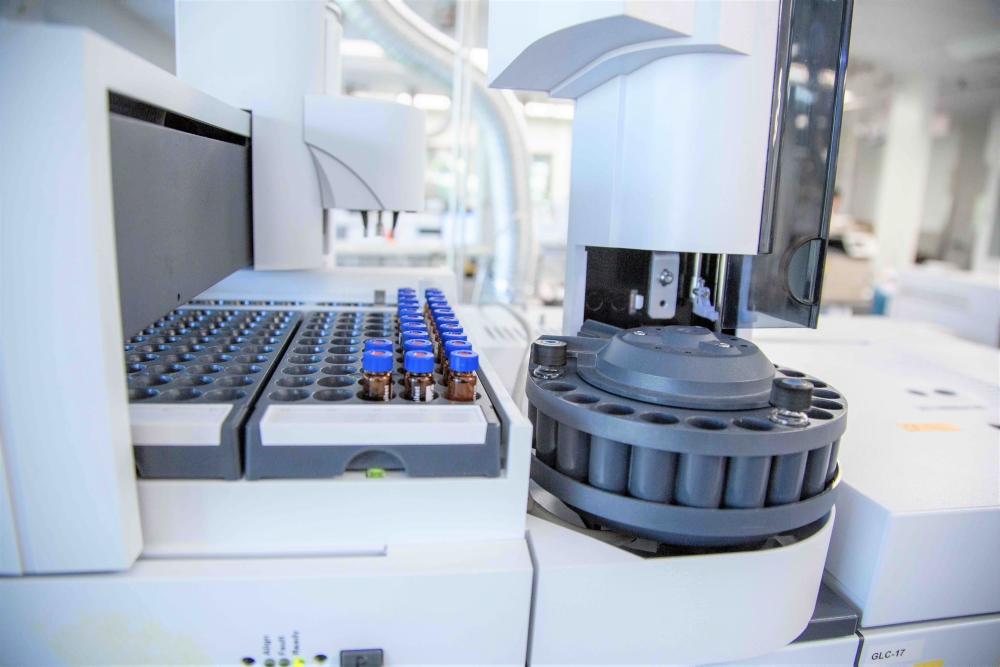

There is also a lot of work from a laboratory perspective. New products must be tested for the presence of various contaminants, as well as the concentrations of the active cannabis ingredients like tetrahydrocannabinol (THC) and cannabidiol (CBD). Health Canada mandates that products must be tested using validated methods.

Method validation is a process that ensures the parameter of interest is detected consistently, reliably and accurately, without interference. The same sample preparation protocols and analytical testing methods used to test cannabis and cannabis oils cannot be assumed to work on other products.

Each new edible product is comprised of a wide variety of different chemical compounds and there may be compounds within those products that can impact the testing process. In addition, the physical properties of the product will impact how labs can obtain a representative subsample of the product for testing.

This means that each new product that is developed must undergo method validation to be able to test for the active cannabis ingredients and potential contaminants. Method validation can be a long and difficult process, often taking several weeks or even months.

If potential interferences are identified, ways to eliminate those interferences must be proven and established before the method can be used.

There are several different methods needed to test for all the different elements and compounds necessary for ensuring a product is compliant with regulations. Since each of these methods must go through the validation process for each new product that is developed, method validation can severely impact the timelines to bring a new edible product to market.

Importance of Homogenous Samples

Establishing appropriate sample preparation processes prior to laboratory analysis is also extremely important. Laboratory analyses for things like water and air are typically conducted on small (frequently milligram-sized) subsamples of the product being tested.

The assumption is that a small subsample is representative of the whole sample and even a whole batch of product. It’s critical that the whole sample is homogenous so that subsample is representative.

In contrast, many foodstuffs, liked edibles, are often very non-homogenous. Think of a chocolate chip cookie. By its very nature it is not homogenous. Various ingredients are concentrated in different parts of the cookie. If the laboratory is given a cookie to analyze, it’s very important to establish a robust way to homogenize the cookie and take a representative subsample of that cookie for analysis.

Contaminants

Another aspect of bringing edible products to market is the question of contaminants, such as herbicides or pesticides, in the final product. Cannabis regulations are quite restrictive on the types of pesticides that can be used in cannabis production, as well as on the limits of pesticide residues permitted on dried cannabis flower and cannabis oils that can be sold to the public. In contrast, there are many herbicides and pesticides permitted in the production of various food products.

This can lead to discrepancies on the permitted concentrations of contaminants within the various constituents used to produce the edible. It remains to be seen how these discrepancies might eventually impact edibles production and the overall edibles market.

It should be noted that the impact of a pesticide on human health may be quite different if the pesticide is inhaled through a smoking or vaporization process rather than if the pesticide is ingested as a foodstuff and passes through the digestive tract. People need to be aware that cannabis products should only ever be consumed as intended by the producer of those products.

Worth the Effort

Clearly there are a lot of factors that go into obtaining suitable samples, subsampling and establishing appropriate methods for edibles. It’s important to use an accredited lab that has scientists with the necessary skills and knowledge to do this work.

It’s intensive and time consuming, but despite the time involved, all these method validation tasks are important to ensure a safe product is delivered to the consumer. That is the reason method validation is required by Health Canada and the additional wait time to bring a new product to market is worth it to ensure edible products are safe.