Inside SRC

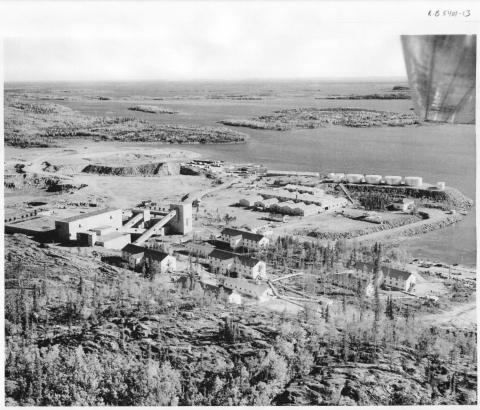

The Gunnar Mine operated from 1955-1963 and officially closed in 1964 with little to no decommissioning. In 1956, it was considered to be the largest uranium producer in the world. Learn about the construction of the site, the operational challenges and the town site that was built - and why it became a ghost town.

Uranium mining companies face a significant processing challenge unique to their industry: the core samples they drill and extract are radioactive. When radioactive material is cut, the dust becomes an issue. Learn how this problem was solved with a custom saw box.

Remediating a contaminated site may have positive and negative impacts on biodiversity. Learn how a sustainable approach to remediation involves planning and implementing environmental protection throughout the entire remediation process.

Giving students the opportunity to try a hands-on experience in science is something we never shy away from. We love science. So, when we heard that youth in northern Saskatchewan were looking for opportunities to gain experience in science-related fields, we took on the challenge.

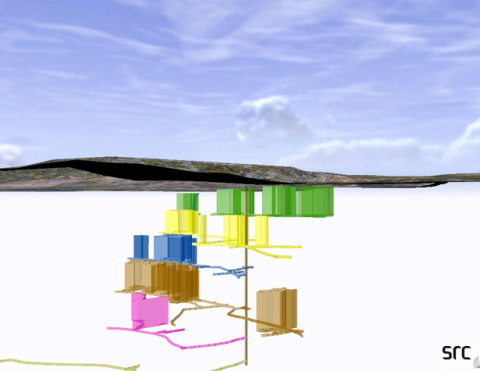

What you can see on the surface of an abandoned mine site doesn’t always tell the full story of the mining activities that took place. In fact, the surface is a very small part of the whole remediation process. Find out how 3-D models of underground workings helps us get a better idea of risks below ground.

Learn about a former Mechanical Engineering student's experience working with SRC's Industrial Engineering team.

This blog was written by former SRC employee, Virginia Wittrock. Every year, Saskatchewan faces the possibility of disaster stemming from natural hazards, such as severe weather, floods, drought and...

Most of us know that Saskatchewan is the world’s richest and largest uranium jurisdiction. But did you know that Rare Earth Elements (REEs) are often found within uranium deposits, making Saskatchewan...

Advanced mining systems enable remote sensing and decision-making for operators and engineers before, during and after mining activities.

In 1960, the Lorado Mill was abandoned in northern Saskatchewan, leaving an estimated 227,000 cubic meters of radioactive uranium tailings that covered the mill site and flowed into nearby Nero Lake. In 2008, SRC was contracted to clean up the site, which began a multi-year journey to reduce the risk to human health, wildlife, and aquatic life.