This blog post was written by Andrew Downing, a former SRC employee.

Uranium mining companies face a significant challenge unique to their industry: the core samples they drill and extract are radioactive. A common aspect of uranium exploration operations includes having radioactive samples analyzed for chemical and mineralogical content.

When the samples reach the lab, the radioactive cores require further processing - it is essential they are handled in a safe and effective manner. Custom laboratory equipment can help solve this unique challenge.

The Process

Depending on what laboratory analysis is required, the cores are cut into sections using a rock saw so selective testing can be done on various parts of the sample. The pieces that are not selected for analysis can be safely stored for further testing and comparing results for quality assurance purposes when necessary.

The Challenge

A typical rock saw is unsafe for cutting radioactive core samples. Cutting samples on a rock saw generates a slurry of coolant (typically water) and rock dust that is sprayed around the area of the saw. For most rocks and core samples this isn't a safety concern. But when radioactive material is cut, the potential for dust becoming airborne is a significant hazard, not just for the saw operator but also for anyone nearby.

Radioactive dust can also spread over and contaminate a large area if the saw coolant is unconfined. A potential solution is using automated saws. These saws are safe to use but awkward and time-consuming. The biggest disadvantage of automated saws is that they don't allow the operator to directly manipulate the core, which can result in the inadvertent destruction of delicate samples.

An alternate solution is to coat the sample in epoxy and then break off a small fragment to create a thin section. While this solution eliminates the generation of radioactive dust, it's slow and the sampled fragment may not contain all the features the company’s geologists may want to see.

The Solution

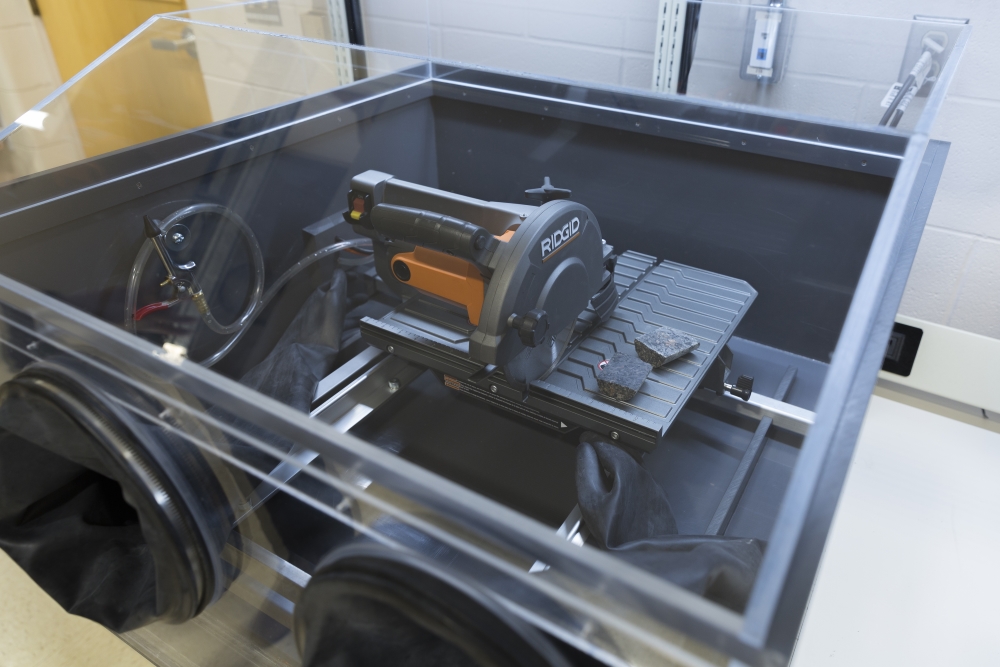

We work with industry, researchers and academics to conceptualize, develop, design and fabricate custom laboratory equipment to suite specific needs. For this challenge, we developed a saw box for cutting radioactive core samples that eliminates the issues associated with conventional core cutting methods.

The saw is contained in a square box with a sealed plexiglass lid and two glove holes. The saw operator can manually manipulate the core in the saw in the same manner as a conventional saw, but the sealed environment keeps the operator safe and prevents radioactive dust from contaminating the surrounding environment.

The saw box also has a recirculating water coolant and wash-down system that contains all radioactive particles and rock fragments. The glovebox core saw is in an isolated laboratory room that is specifically designed to contain particulates to ensure environmental contamination cannot occur.

“This enclosed saw allows us to process clients’ radioactive samples safely and has given us the opportunity to improve the quality of the product we deliver. Providing this level of customization with a commitment to safety is one of the key strengths of SRC.” - Dr. Steven Creighton, Research Scientist at SRC

Analytical laboratories are required to provide services to clients in a safe and productive manner, which need to be effective in stringent laboratory conditions. Through research, development and demonstration, SRC provides unique solutions to successfully help industry conduct research, expand or improve services and solve unique challenges when they arise.

SRC’s Development Engineering team creates solutions such as automating a process, designing and fabricating tools or equipment, or incorporating instrumentation and integrating it with other existing systems. Learn more.