In the 21st century, the computed tomography (CT) scanner has become a mainstay for diagnosing medical diseases. It can see what’s going on inside a person without invasive testing or surgery. But did you know this same technology is also used in the oil and gas industry to better understand reservoirs, optimize oil recovery and develop new or improved ways of producing oil?

That’s right, CT scanners have been used in the petroleum industry for decades. Many commercial laboratories, research institutes and universities around the world have medical-grade CT scanners which they use for petroleum research. They can provide accurate quantitative data around flow patterns, porosity and saturation without altering the fluids or rocks. These scanners provide fine 3-D resolution and are adaptable to many types of experimental techniques, while at the same time keeping the sample intact.

How CT Scanners are used in the Oil and Gas Industry

Imagery data generated from these machines is used to better understand the nature and characteristics of light oil reservoirs by looking at the detailed features of one or more core samples. It can show internal microscopic features, such as grain size and shape, pore size and network, lithology and mineralogy and in-situ fluids distribution.

Together with image analysis, CT scanners are used in a wide range of applications, such as routine and special core analysis, petrophysics, formation damage, petroleum geology, reservoir modelling and digital rock typing.

These medical-grade CT scanners, however, have their limitations.

Since they were intended for analyzing living objects, the energy from these medical-grade X-ray sources is quite low with very limited penetration power. The resolution is commonly only 250-400 microns – roughly one quarter of a millimeter. For comparison, a Canadian dime has a thickness of one millimeter.

High-Resolution Industrial CT Scanners

This is where high-resolution industrial CT scanners come in. They can perform X-ray imaging of core samples at 10 to 100 times higher resolution than a standard medical-grade scanner, meaning that a resolution of 20 to 30 microns is more characteristic. For comparison, the naked eye can only see down to 40 to 50 microns and to be able to distinguish any details, such as colour, the range needs to be 75 to 125 microns.

This opens a window for researchers to conduct many tests that either aren’t available or are too labour intensive with standard methods. Some examples include ore and mineral analysis, electronics component inspection, welding/bonding quality verification, museum artifact digitization, medical and pharmaceutical device inspection and mass product quality control.

In the Lab

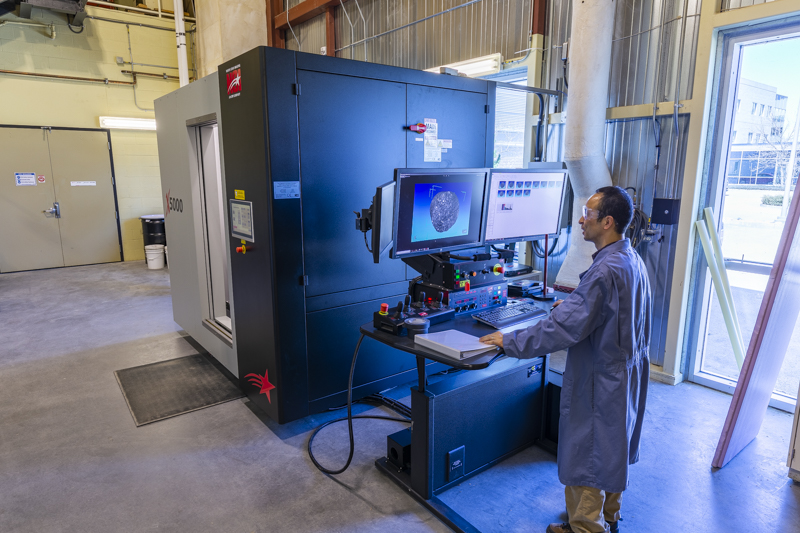

SRC’s Energy Division is the first dedicated petroleum research and development laboratory in Canada to use a combined mini- and micro-industrial CT scanner. This scanner is four to five times more powerful than the usual hospital CT Scanners and can operate in two power modes.

The highest power mode allows researchers to use very high-power X-rays to look inside materials that are encased in thick high-density material and see deep within the test material. The second power mode allows researchers to see extremely small details much finer than the width of a human hair in amazing detail, albeit at a smaller overall sample size than the higher power mode.

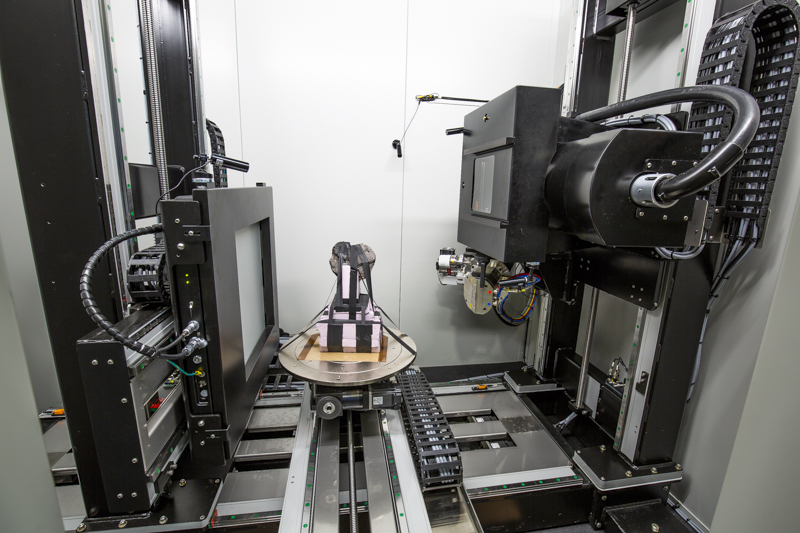

The scanner can handle a variety of core sample width and weights because of its spacious interior and adjustable tube-to-detector distance. This means a research engineer can test a 1.5-meter long core stack or a 5-inch diameter core plug. We can also scan tiny objects, such as diamonds that are less than 1 mm in size at a resolution of 5 microns.

How an Industrial CT Scanner Works

The scanner works by rotating samples and capturing images of what the X-ray looks like at each perspective. Typically, samples are rotated 360 degrees on a horizontal stage, and a few hundred to thousands of 2-D images are taken at a constant time interval during the full rotation.

The type of X-ray tube used depends on the size and density of the objects being scanned. For example, the mini-tube was recently used for a large carbonate sample from the Midale Beds in the Western Canadian Sedimentary Basin. The micro-tube was used for some submicron-diamond research work at SRC Geoanalytical Laboratories.

Depending on the needs of the client, SRC typically then takes these 2-D images and creates a more in-depth 3-D model from them using specialized reconstruction software. From there, our researchers and engineers can complete various diagnostics and analytical techniques to find out more information about the core sample.

Through this work, SRC can provide our oil and gas industry clients with more thorough oil recovery data, which helps them to understand oil recovery mechanisms, optimize processes and accurately define the physics and chemistry in the reservoir models.

The CT Scanner is owned by the Petroleum Technology Research Centre, which received an $800,000 investment from Western Economic Diversification Canada, and additional funding from SRC and the University of Regina. It was installed and commissioned at SRC’s Energy laboratories in Regina in April 2018.