QEMSCAN

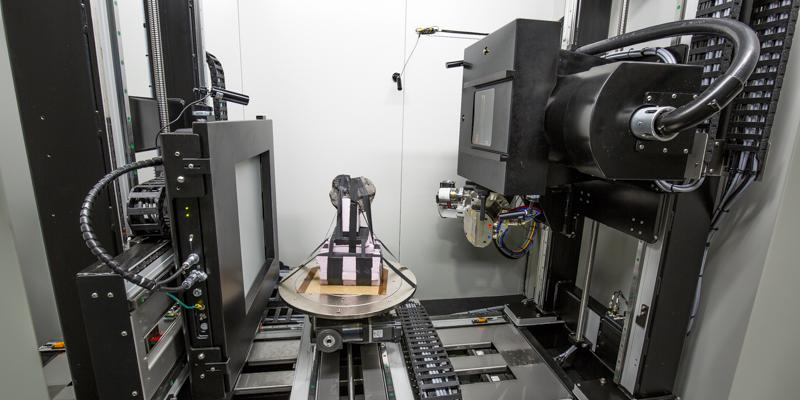

SRC uses a variety of analytical techniques for mineral exploration and mining, including automated mineralogy using QEMSCAN® analysis.

SRC's Advanced Microanalysis Centre™ and Geoanalytical Laboratories can handle all types of ores and have specific expertise in preparing and analyzing clay-altered samples, radioactive materials, uranium, kimberlite, potash and base metal sulphide ores by QEMSCAN® analysis.

SRC is the only CNSC-licensed facility for thin section preparation in Canada.

Our team has developed specialized techniques that combine QEMSCAN® imaging to determine the applicability of sensor-based sorting technologies (e.g., XRT, laser, NIR). This technique offers non-destructive ore characterization.

Applications

In mineral exploration, QEMSCAN® imaging can be used to provide a quantitative modal analysis and core for target prioritization. QEMSCAN® analysis is used in mineral processing to assess the key characteristics of targeted minerals in order to design more efficient recovery processes and for diagnostics, if recoveries are not values that are expected.

In oil and gas exploration, QEMSCAN® analysis can be used to quantify and characterize the porosity of fine-grained reservoir rocks as part of the modal mineralogical analysis.

Automated analysis by QEMSCAN® imaging can increase reproducibility in data quality and reduce operator bias. Early adoption of QEMSCAN® analysis in an exploration program can provide the geometallurgical framework for determining the mineralogy and the confidence in preferable ore characteristics for mineral processing and potential extraction methods.

Services

- Sample preparation

- 30-mm diameter (metallurgical) block mount preparation

- Pseudo-core preparation (for very coarse-grained samples)

- Analytical

- Quantitative modal mineralogy

- Elemental deportment

- Grain size distribution

- Target mineral liberation and associations

- Grade recovery prediction

- Quantitative mineral chemical composition by electron microprobe analysis

- Data compilation and report preparation

- Sensor-based sorting

Scanning Electron Microscope (SEM) Analysis

SRC’s uses state-of-the-art equipment to perform high-magnification imaging for clients in the exploration and mining industries. The scanning electron microscope (SEM) creates high-magnification images. This technology is widely used as an important tool for imaging material surfaces, as well as for identifying chemical signatures.

Key Features

- Common minerals and alloys rapidly identified by their unique chemical composition using an electron dispersive spectrometer (EDS), without the need for special coatings or preparation

- Capable of using secondary electrons and back-scattered electrons for imaging

Mineral Chemistry (Microprobe)

SRC’s expert team uses an electron probe micro-analyzer (electron microprobe EPMA) to perform highly sensitive chemical analyses of micro-volumes of properly prepared samples. This provides the greatest possible sensitivity for quantitative analysis, from boron to uranium.

Applications

- Indicator mineral chemistry

- Minor and trace gold in sulfide minerals (cryptic gold)

- Purity of metal alloy catalysts

- Quantification of deleterious elements in high-purity materials

- Rare earth element (REE) analysis of heavy mineral concentrates

- Element diffusion profiles in metals and minerals

- Forensic analysis of process contaminants (e.g. Pb in plumbing solder)

- U-Th-Pb analysis for chemical dating of uranium minerals

Quantitative Sample Analysis (XRD)

SRC uses a well-established system for process and quality control of minerals and ores. The X-ray diffraction (XRD) system at SRC’s Advanced Microanalysis Centre™ is a powerful tool used to characterize mineral indicating clays. It permits both qualitative and quantitative analysis of phases or compounds present in samples.

Key Features

- Effective method for determining the bulk/clay mineralogy using random/oriented mounts

- Automatic sample changer with three types of sample holders for powder and clay samples (back-packed, vacuum filtered and zero background)

- Data analyses and interpretation using algorithms in MDI Product JADE v.9 software, including search/match and whole pattern fitting plug-ins

- Reference data from the American Mineralogist Crystal Structure Database with empirically derived relative intensity ratios

Quantitative XRD

Analysis – This technique is used to determine the abundance of minerals in a sample. Minerals present in low abundance (<2%) may not be reliably identified or quantified. Amorphous material cannot be quantified.

Sample – Requires a minimum sample of 25 g

Contact us today to schedule your service.