A previous version of this article was published by CIM Magazine.

From exploration projects to operating mines, preconcentration, and specifically sensor-based ore sorting, is becoming a critical step in improving both project economics and sustainability. Mining companies face constant pressure to improve recovery, performance, lower processing costs and reduce environmental impacts.

Laser sorting is one of the latest technologies being implemented in the mining industry to help separate valuable ore from waste early on in the process. By upgrading ore prior to transport or before it reaches the mill, laser technology reduces the volume of material processed downstream, leading to lower energy use, cleaner tailings and more efficient operations overall.

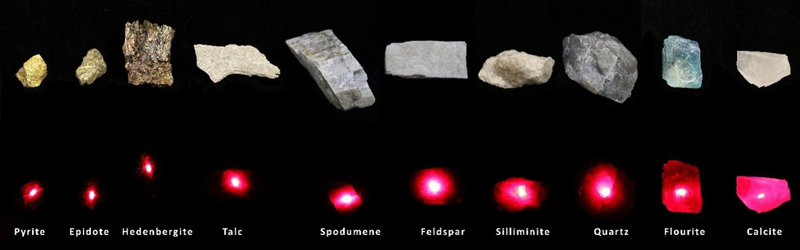

The concept of laser scattering is built on the principles of light-matter interaction and has a number of applications, from scientific research to industrial processes. Laser scattering involves the interaction of lasers with particles or surfaces, resulting in light dispersion. By analyzing the intensity, wavelength and direction of scattered light, insights into particle size, shape and composition can be collected (Figure 1).

At SRC, we apply these scientific principles directly to mining challenges, using a standardized approach developed in-house, to turn bench-scale testwork into practical, economic solutions for industry. With decades of experience in sensor-based technologies for commodities such as diamonds, SRC has developed significant expertise and capacity to help industry navigate sorting technologies and test and implement them into their processes.

Sensor-Based Sorting: Why It Matters and How SRC Supports Industry

Sensor-based sorting (SBS) has grown significantly in the mining industry over the past decade, driven by the need for efficiency, cost reduction and sustainable practices. Laser-based particle sorting systems are a subset of SBS that use laser technology to differentiate and separate valuable mineral ores from waste rock based on their optical properties. The technology has been successfully implemented in both greenfield exploration and brownfield mining operations.

At SRC’s Minerals Liberation Sorting Centre, we operate an X-ray transmission (XRT) sorter with an additional electro-magnetic (EM) sensor bar, a final recovery XRT sorter and a full-scale multi-channel ore sorter capable of laser, visible, near-infrared and EM detection, or a combination thereof. In practice, the laser, visible and NIR sensors measure how particles reflect and absorb light across different wavelengths. This allows the sorter to distinguish between materials based on colour, brightness and mineral-specific spectral signatures, such as separating quartz-rich rock from carbonate or clay-bearing material.

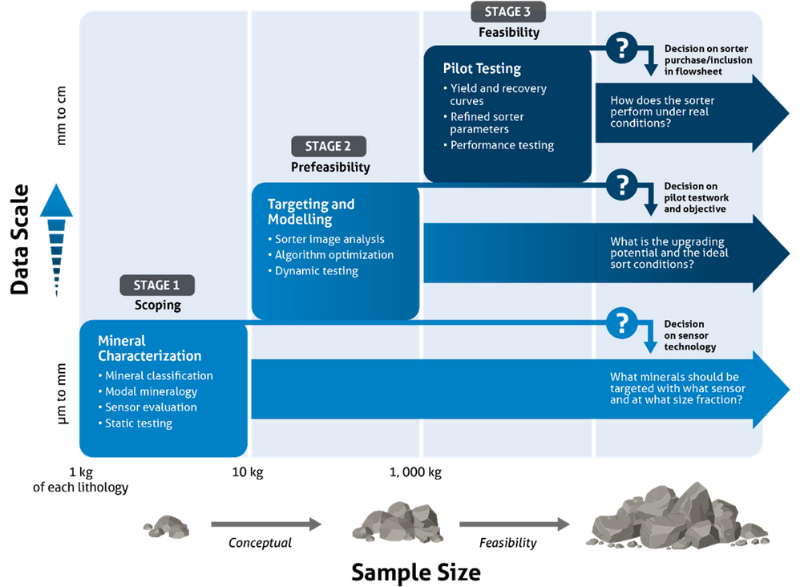

Used after the primary stage, the multi-channel laser sorter performs finer, more selective separation to improve product quality and recovery, giving industry access to one of the most advanced sorter testing platforms available in Canada. Our team can take projects from initial ore characterization, analyzing just a few kilograms of rocks, through bench-scale trials and pilot testing, processing up to hundreds of tonnes of material.

All of this work, including preparation such as crushing and sieving, happens within a single facility (Figure 2). This integrated workflow saves clients time and ensures consistent results from start to finish.

The Science Behind Laser Sorting

Laser sorting exploits the scattering properties of light in minerals. When a laser beam interacts with a particle, the light is scattered to varying degrees depending on the mineral’s structure and composition, creating a measurable glow. Translucent minerals, such as quartz, scatter light throughout their crystals, while opaque minerals show little to no measurable scattering. Detectors capture these differences in pattern and intensity, allowing the system to identify and separate valuable minerals from waste based on their unique optical responses.

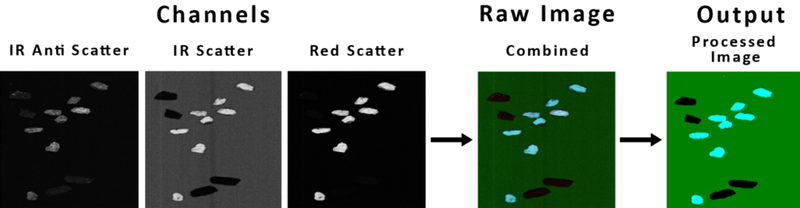

At SRC, we utilize a multi-channel laser ore sorter equipped with four available channels, red, green, blue and infrared (IR), configured and paired with its own photomultiplier tube (Figure 3). This configuration allows us to measure how each wavelength of light diffracts and reflects as it interacts with a particle.

The system can filter responses to measure both scatter and anti-scatter, capturing the light that is transmitted through a particle, as well as the light that is reflected back (Figure 4). This dual view provides a more complete optical profile of each particle, increasing accuracy.

By combining multiple laser wavelengths, the sorter can evaluate particle brightness, colour, transparency and surface features, providing a precise basis for differentiation. This multi-channel approach is particularly effective for separating materials that may appear similar to the naked eye. To achieve consistent results, material must be clean and presented in a single layer.

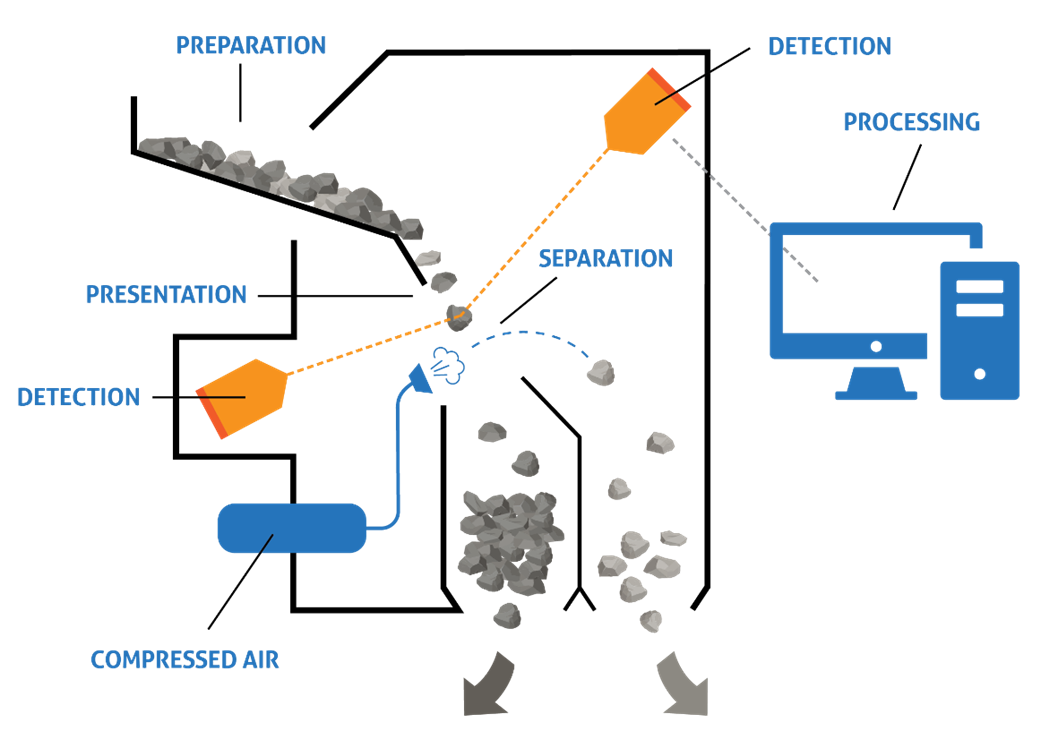

Typical laser sorters, such as those used at SRC, are chute-fed systems that use air-actuated valves to separate ore from waste. Precise coordination between sensors and valves is critical to maintain accurate particle separation (Figure 5). During the third testing stage at SRC, equipment is operated at production speeds of up to 100 tonnes per hour, allowing our team to assess the sorter’s full-scale capabilities and refine parameters for commercial applications.

Case Study: Quartz-Hosted Gold

Laser sorting has proven highly effective for quartz-hosted gold deposits. Gold itself is not directly detectable with current sensors, so separation relies on identifiable proxies, like quartz. These deposits typically feature gold-bearing quartz veins within various host rocks. They form from silica-rich hydrothermal fluids, which may contain gold, migrating upward through fractures and faults and precipitating as they reach lower pressures.

This process forms gold-hosted or barren veins, depending on the fluid's gold content. Gold within these systems is often associated with minerals such as sulfides (e.g., pyrite, arsenopyrite) and may exhibit multiple stages of mineralization and remobilization.

At SRC, through discussions with the client and internal analysis, we begin by characterizing the ore to determine the proportion of quartz, its association with sulfides and the variety of lithologies present.

Ore characterization studies can include detailed mineral analysis to determine overall composition of both the mineralized and barren fractions. This can also highlight penalty elements, which may be beneficial to remove early in the process. Understanding the ore upfront is critical to optimizing a sorter’s performance and ensuring calibration for the best results.

These deposits can prove challenging to mine, as the gold is typically finely disseminated within the quartz matrix, and the ore itself is usually complex. Traditional sorting methods, such as manual sorting and gravity separation, often fail to effectively distinguish between quartz with high gold content and barren quartz.

Quartz is a hard mineral that requires significant energy to crush, and without efficient separation of gold-hosted from barren quartz, processing costs rise and recovery falls. A properly calibrated laser sorter can upgrade feed before milling, reducing downstream energy use and improving recovery.

Once the mineralogy is determined, the scattering response of the different minerals can be compared to determine the optimal sorter configuration. By assessing the relationship between light scattering behaviour and grade (for example, gold content), our operators fine-tune the laser’s settings to maximize recovery and minimize mass pull.

This optimization work is included in SRC’s test programs and is scalable, providing clients with real performance data before committing to commercial installations.

Laser technology detects subtle differences in the mineralogical composition of ore-bearing and barren host rock (Figure 6). Gold-bearing quartz often has minor variations in texture, colour and surface characteristics compared to barren quartz, while the surrounding host rock has a distinctly different optical signature. Differences in light-scattering properties between these materials enable effective separation of gold-bearing quartz from waste, improving both recovery and process efficiency.

The Value of Laser Sorting

Laser sorting can significantly improve both the economics and sustainability of mining operations. By selectively isolating and concentrating higher-grade material, the technology upgrades low or marginal-grade deposits and increases the overall grade of the ore. This improved selectivity can enhance the economic viability of deposits that might otherwise be uneconomic to mine.

The environmental benefits are also significant, although they can differ for greenfield and brownfield applications. In general, by efficiently separating waste rock from ore, laser sorting reduces the volume of material that needs to be processed downstream, lowering energy consumption and decreasing emissions.

In addition, the process is dry and chemical-free, which minimizes water use and eliminates reagents, further reducing environmental impact at this stage of the process.

Early removal of penalty elements and deleterious minerals improves downstream processing efficiency and results in cleaner tailings. For many clients, this can mean moving projects forward that might otherwise remain stalled due to economics or sustainability constraints.

Supporting Industry to Unlock Ore Potential

By combining detailed ore characterization, multi-channel laser dual-sorter detection and a rigorous stepwise testing approach, SRC provides the mining industry with the insights needed to make confident decisions about full-scale sorter deployment. Whether you are in early exploration, or optimizing an operating mine, our integrated Minerals Liberation Sorting Centre can help unlock the potential of your ore.

Learn more about SRC’s sensor-based sorting and mineral separation services at src.sk.ca/services/sensor-based-sorting or contact our team to discuss how laser sorting could support your project.