Radioactivity in mining is commonly associated with uranium but there are numerous other sources of it that can be found in the mining industry. While radioactivity is a natural phenomenon that needs to be managed, there are also cases where it can be used as a tool in driving exploration forward. It’s important then to understand what radioactivity is, how it’s encountered and the risks and benefits associated with it.

SRC has tackled the ever-changing landscape of industry needs since 1947 – finding real-world solutions to evolving challenges through innovation. Learn how SRC's mining services and facilities have evolved over the years from an industry expert.

While potash has some valuable industrial uses, 95 per cent of the world’s production goes towards supporting the agricultural industry. As demand for a variety of food crops increases, farmers and industry are looking for premium fertilizer to maximize their yields. Learn how SRC is helping industry recover premium products, such as sulphate of potassium.

Rob Millar’s nearly two-decades long career started at SRC Geoanalytical Laboratories in 2005 in sample preparation. He then moved into an analyst role and eventually became lab manager. Learn about Rob's career at SRC and how he and his team have helped develop solutions to meet the evolving needs of industry.

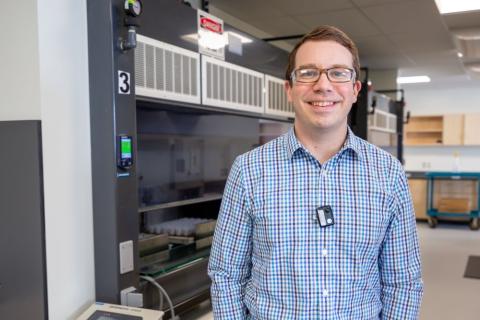

Meet Mike McCubbing, manager of SRC's Diamond Laboratory - one of the largest commercial diamond processing labs in the world. Learn more about Mike's career at SRC and how his team has helped grow SRC's diamond capabilities to meet evolving industry needs.

As electric vehicle technologies advance and the energy transition continues, the demand for critical metals keeps rising. Learn about SRC's direct recycling process of LIB metals that will help industry meet the growing demand for critical metals and divert batteries from landfills.

Dr. Jack Zhang and SRC's Mineral Processing and rare earth experts are making waves in industry with their innovative approach to developing processes for ore beneficiation, separation and hydrometallurgy. Learn more about how Zhang built a mineral processing team at SRC from the ground up and what's next for rare earths. Read on.

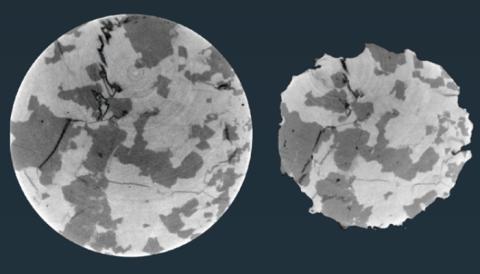

Potash solution mining is used for extracting ore from deep underground, but unlike conventional mining, operators don't have direct access to the potash bed to analyze the geology. This is where SRC's industrial computed tomography (CT) scanner comes in. Learn how CT scanning can help mines better understand their deposits.

The way we extract and process resources is constantly changing. The practices and technologies (and legacies) in place today reflect past industry standards. What are the potential legacies of the future? How can we avoid them? Four industry experts weigh in.

X-ray transmission (XRT) sorters are a popular choice for mineral processing plants due to their sorting ability, robustness and applicability across a variety of ores, but how can a mining company know if XRT is right for them? Learn how SRC experts combine technologies to help find the answer.