This article first appeared in the Canadian Mining Journal and is co-written by SRC's Nathan Peter and Andrew Downing.

Mining companies across Canada are experiencing challenges in lowering costs, increasing productivity and improving safety in mining processes. Advanced mining systems can help industry overcome these challenges by offering improved communication systems. The systems are a suite of technologies and services that enable remote sensing and decision-making for operators and engineers before, during and after mining activities.

Improving Mine Communications

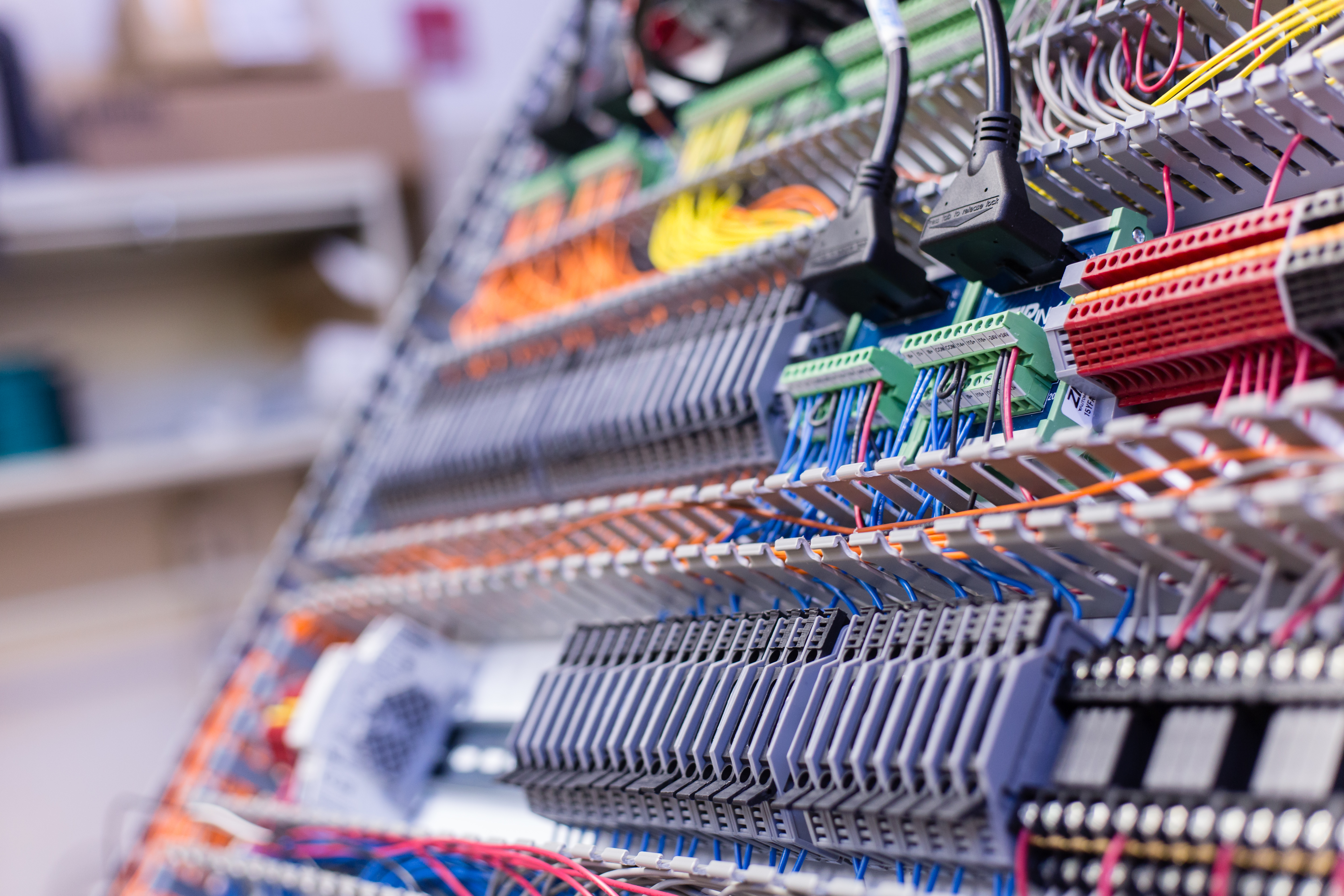

One example of an advanced mining system is data communication systems, which are key to connecting control systems with remote sensors in active mine operations. Effective real-time communications allow process control and survey data to be observed by equipment operators, as well as provide the front-end data gathering services for mine planning information systems. A common problem for communication systems in mines is that signals can be interfered with due to the presence of metallic ore, background noise, long distances and physical inaccessibility. To combat this, specialized engineering solutions can work within the constraints of unique and challenging conditions.

At SRC, we've researched several methods of data communications suitable for mining operations. Wireline and drill strings have typically been key focuses for our team, due to industry trends of drilling smarter, as well as developments in targeted remote ore extraction. Several technologies for data communication have been developed and demonstrated by us using drill strings and pipelines. For example, acoustic waves, electromagnetic waves, light waves and powerline modems can be used to carry signals through various mediums, providing data from simple temperature sensors to high bandwidth video streams.

Real-world Application

We work closely with mine engineers to apply these technologies in field operations, effectively creating new capabilities that would have otherwise not been possible. For example, in-situ cavity survey systems that are embedded in underground extraction tools. Comprehensive solutions typically consist of electronics, embedded sensors, electronic data communications, mechanical housings and the field deployment services. These technologies can be applied or combined with additional technologies to improve other processes as well. The end result is automated processes that are quicker and safer for operators. In addition, information from the survey system is made available for further analytics and planning, improving overall mine efficiency.

Mining companies face challenges of expanding their capabilities and managing costs, levels of productivity and safety issues in mining related activities. By researching, developing and demonstrating effective technology solutions, companies like SRC can help industry overcome these challenges and successfully improve and optimize mining operations.