Rare Earth Processing Facility

Since 2020, SRC has been building a state-of-the-art minerals-to-metals Rare Earth Processing Facility in Saskatchewan with funding from the Government of Saskatchewan and the Government of Canada. The Facility is complete with hydrometallurgy, separation and metal smelting stages – each using cutting-edge in-house developed and built proprietary technologies, designed with operator safety and sustainability top of mind. The Facility is scheduled to be substantially completed in September 2026, commissioned by December 2026, and after a production ramp-up phase, operational within the 2027 calendar year.

SRC's Rare Earth Processing Facility will produce magnet-grade neodymium praseodymium (NdPr) metal and dysprosium (Dy) and terbium (Tb) oxides.

Latest News

SRC and REalloys, Inc. sign historic rare earth partnership agreements, advancing North American independence in rare earths and positioning Saskatchewan as a global critical minerals hub.

Stay Up to Date

Subscribe to our newsletter to receive the latest news on SRC's Rare Earth Processing Facility.

Trailblazing an Industry

Learn about the development of SRC's Rare Earth Processing Facility - from getting the initial go ahead to designing and building cutting-edge technologies.

Facility Milestones

- 2020: SRC Rare Earth Processing Facility announced by the Government of Saskatchewan

- 2021: Monazite feedstock secured from Brazil

- 2022: The Facility produces its first rare earth metal ingots

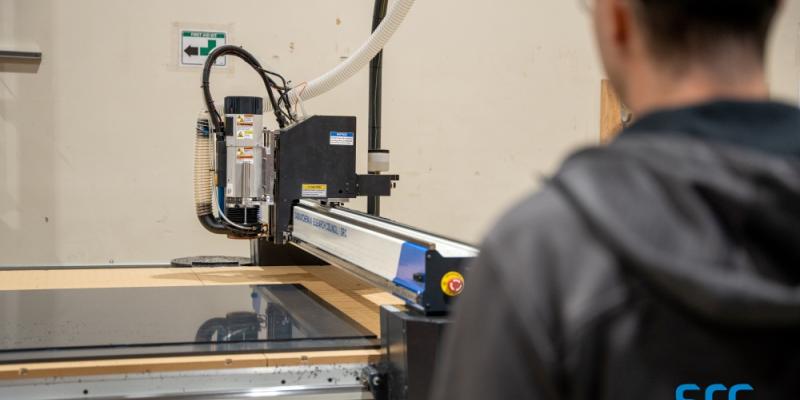

- 2023: In-house fabrication of SRC's proprietary solvent extraction (SX) cells begins

- 2024: SRC begins to establish and commercialize a process to separate unrecovered rare earth oxides from monazite tailings

- 2024: The Facility achieves commercial scale production of rare earth metals

- 2024: Bastnaesite is acquired from a Canadian source and SRC begins building bastnaesite processing capability

- 2025: Fabrication of SRC's SX cells is completed

- 2025: SRC and REalloys sign major partnership agreements

Contact us

Questions? Get in touch with our team.

Building Value

Since beginning the project, SRC’s Rare Earth Processing Facility has expanded to go even further down the midstream rare earth element (REE) value chain than initially planned – producing NdPr metal and Dy and Tb oxides.

These metals are essential for high-efficiency permanent magnets, which are vital to modern technologies such as electric vehicles, wind turbines and defense systems. SRC’s Rare Earth Processing Facility will produce enough REE metals to power more than 500,000 EVs each year.

“Having the ability to produce commercial-scale metals at our facility gives the rare earth market in Canada a boost. We’re helping speed up the development of the rare earth industry by building the commercial-scale processing capability right now.”

- Mike Crabtree, SRC President and CEO

SRC is exploring the licensing of solvent extraction processing technology that separates rare earth elements. This includes the design, fabrication and installation of custom-built, proprietary, artificial intelligence-controlled solvent extraction cells, as well as separation processes.

SRC is exploring the licensing of metal smelting technology, which includes a metal smelter that is equipped with automatic process controls to improve efficiencies and operator safety.

Contact us

To learn more about about licensing our technologies or to find out more about our Rare Earth Processing Facility

- Stirring Things Up: SRC Advances Metal Smelting Technology - Read

- SRC Rare Earth Processing Facility First to Produce Rare Earth Metals in North America - Read

- Minister Wilkinson Announces Investment in Critical Minerals in Saskatchewan - Read

- Minister Vandal Announces Investment in Processing of Rare Earth Elements in Saskatchewan - Read

- NRCan Funding Advances Technology at SRC's First-of-Its-Kind Rare Earth Processing Facility - Read

- How SRC is Using Metal Smelting for Rare Earths - Read

- $7.5M for Rare Earth Elements Processing Facilities in Saskatchewan - Read

- SRC Achieves a Significant Milestone in Advancing Canada's Rare Earth Element Supply Chain - Read

- Government of Saskatchewan Provides Additional Funding for SRC Rare Earth Processing Facility Expansion - Read

- SRC Signs Memorandum of Understanding with KOMIR on Critical Minerals - Read

Interested in bidding on work?

SRC Purchasing handles all requests for proposals, estimates and quotations to solicit bids for procurement contracts related to this Facility. Available opportunities will be posted on SaskTenders (Organization Type: Crown Corporation > Saskatchewan Research Council).

For more information, please contact SRC Purchasing by email or phone at 1-306-933-5400.