3-D Scaled Physical Modelling

SRC houses a state-of-the-art physical model laboratory to study a variety of hybrid thermal-solvent (TSVX) based enhanced oil recovery processes. Using the largest known physical modelling apparatus in the world, these studies are intended to provide a clearer understanding of rate controlling mechanisms for the purpose of accelerating the development, deployment and optimization of these processes for the heavy oil and oil sands industries.

The hybrid TSVX physical model operates at high temperatures, which enables researchers at SRC to evaluate and develop the full spectrum for steam-solvent processes.

History matching of the experimental runs using advanced algorithms provides for the calibration of numerical simulators predicting field-scale performance. Coupled with comprehensive economic models, both the technical and the economic viability can be determined for the TSVX process.

The physical model apparatus consists of the overburden pressure vessel (OBV) system rated for 10.5 MPa, working pressure at 10 to 250 C for TSVX processes. The OBV can operate in both the horizontal and vertical positions, and can accommodate large physical models with a vertical reservoir thickness of up to 2.5 metres, pore volumes between 80 and 180 litres for TSVX that contain either vertical or horizontal wells and any type of porous media, and can accommodate the injection of any combination of liquids and/or gases.

We offer analytical tests and property determinations required for 3-D physical and numerical modelling of TSVX processes:

- Equation of state (EOS) determinations to generate steam-solvent-temperature diagrams

- Special pressure, volume, temperature (PVT) analysis to determine oil viscosity, density and vapour-liquid equilibrium (VLE), TSVX - pseudorelative permeability determinations

The overburden pressure vessel in the horizontal position in the TSVX laboratory.

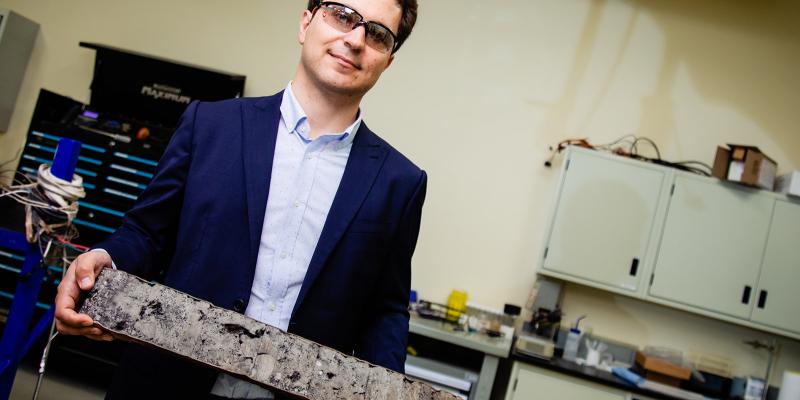

Wet test meters in the TSVX laboratory.

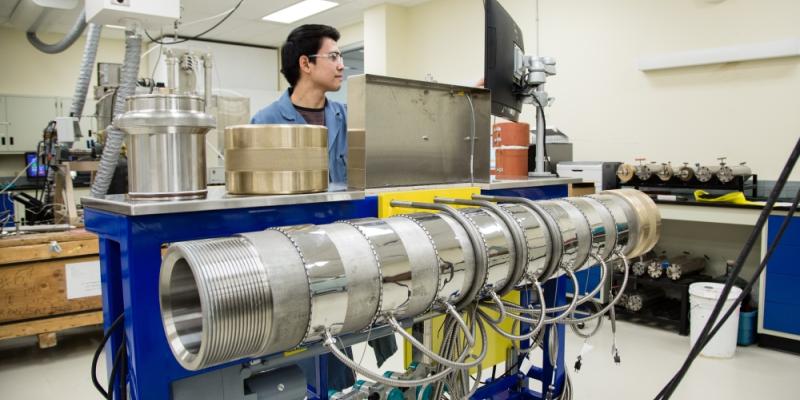

The solvent vaporizer in the TSVX laboratory.

The production vessels and flow control valve in the TSVX laboratory.

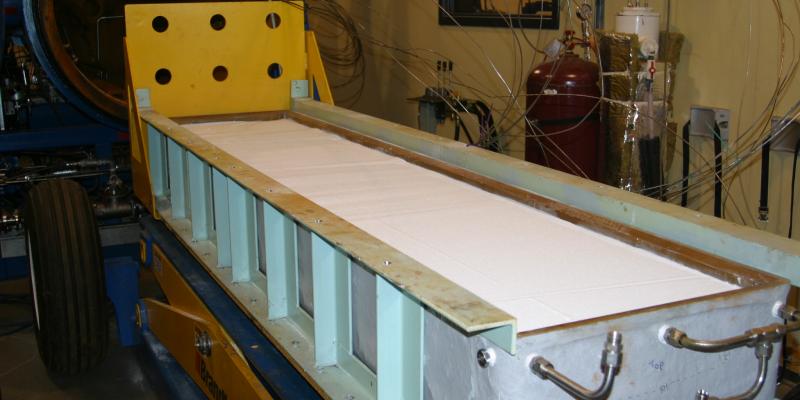

The tub and lid design fiberglass 3-D physical model packed with glass beads.